Extrusion

Shining Opportunities In Solar Films

Photovoltaic markets are growing explosively, and so are opportunities for specialty film producers. Solar cell and module production, which was forecasted to grow at 50% a year for the next few years before the recession hit, is now expecting slightly more healthy 30% annual growth, according to DuPont, a major supplier of photovoltaic film materials. Solar cell and module manufacturers are expanding, and large numbers of new companies are entering the field.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreStop Die Buildup

Die buildup, also called die drool, die bleed, or plate-out, can plague any extrusion process.

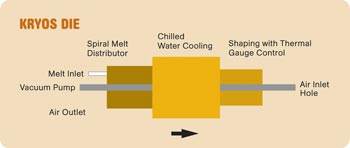

Read MoreAir/Water Cooling Die Doubles Output of PE Pipe

A new high-output extrusion die for large HDPE or PP pipe (110 to 2000 mm OD) combines water-cooling of the melt before it leaves the die with air cooling inside the pipe.

Read MoreMichigan Plastics Machinery Moves

Michigan Plastics Machinery (MPM), a maker of downstream equipment for pipe and profile extrusion, has moved from Kawkawlin, Mich., to nearby Bay City.

Read MoreNew Source of Crossheads

WEB EXCLUSIVE JoeTools, a supplier of plasticating components for extrusion and molding, is expanding its product line with ThermoGuard insulated crossheads for building and communication wire, medical tubing, hose, and pipe.

Read MoreHigh-Speed Extrusion: Are You Ready for the Fast Lane?

Around three dozen, mostly European, processors are pushing commercial development of high-speed single-screw extrusion. They have installed more than 100 of the small hyper-drive machines whose screws turn at up to 1500 rpm, about eight to 10 times faster than standard extruders. At least two German machine builders are working on machines that will go to 2000 rpm and even higher. The goal is to raise output without increasing extruder size.

Read MoreDon’t Wind Wrinkles Into Your Film

Wrinkles are a major cause of defects in extrusion winding and converting, especially with thinner films, which are much more wrinkle-prone than thick ones. The cause of most wrinkles is located close to the roller where the wrinkle first appears and can be identified by looking at the orientation and pattern of the wrinkle. First, find the cause; then try to eliminate or at least reduce it.

Read MoreInvesting in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

Read MoreAmerican Kuhne Moves

Extrusion equipment supplier American Kuhne, Inc., has moved from Norwich, Conn., to a 12-acre site in Ashaway, R.I., which is much closer to Providence airport.

Read More