Extrusion

Seven-Layer R&D Line Spurs Blown Film Innovation

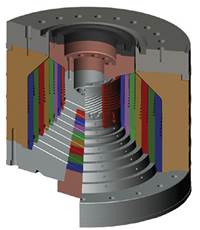

Business might be slow in most blown film extrusion markets, but leading-edge processors are preparing for better times by tapping into a seven-layer line installed last year at Dow Chemical Co.’s Film Application Development Center (FADC) in Freeport, Tex.

Read MoreHow Much Regrind Can You Handle?

Most extrusion operations generate scrap, and in the case of sheet for thermoforming it can exceed 70% of total output.

Read MoreWhere Are You Using Energy?

Few plants are able to accurately divide up their energy consumption by where it occurs, despite the fact that this is relatively easy to do.

Read MoreDon't Get Burned by Adapters & Flow Pipes

Does degraded or burned polymer seem to show up when you least expect it?

Read MoreCommunication Is Key in Designing Blown Film Dies

Over the years I have bought, designed, or helped design quite a number of blown film dies.

Read MoreHaving Output Problems? Check Your Feed-Port Design

With an extruder, like all other devices, “it can’t come out unless it goes in first.” That’s the first thing I remember when I am asked to figure out why an extruder is performing below expectations.

Read More'Do-It-All' Approach Keys One Processor's Growth

What shape will the successful North American plastics processing operation take as we move through the next decade?

Read MoreTooling Know-How: Five Tips on Profile Die Design

A poorly designed profile die—one that does not permit the part to be extruded with the same dimensions from run to run—coupled with a lack of understanding of the extrusion process, is a recipe for scrap generation.

Read MoreSustainability Drives Innovation at Leading RPET Processors

Two Southern California processors have boldly gone where no one has ever gone before.

Read MoreExtrusion Know-How: The Whys & Hows (& Ifs) of Vented Extruders

Vented or two-stage screws only make sense when volatiles must be removed in order to make a satisfactory product.

Read More