Injection Molding

Engel North America Launched Apprenticeship Program

Certified and registered within the Commonwealth of Pennsylvania, the program lasts four years with a combination of on-the-job experience and classroom-based instruction.

Read MoreBockatech Pushes New Boundaries at K 2022

Three years after debuting at K 2019, Bockatech’s EcoCore technology is boasting faster cycle times and lighter containers with greater properties as it targets more verticals and broader brandowner adoption.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreThe Secret to Molding with PCR: Don’t Fear Variation – Embrace It!

“Embrace variation” – That contradicts all normal thinking about processing plastics. But the only thing that’s “normal” about recycled plastics is variability, and that requires a processing philosophy that assumes variation and is geared to deal with it.

Read MoreMold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreAI-Based Injection Molding Assistant Launched

LS Mtron’s new AI Molding Assistant and Smart Weight Control technologies can help molders reduce costs while achieving higher quality and productivity.

Read MoreEngel Names New President for North American Operations

Vanessa Malena will become the new president of Engel Machinery Inc., succeeding Mark Sankovitch and after promotion from COO.

Read MoreNew Graph Interpretation Course for Injection Molding

RJG’s newest training course—Graph Interpretation for Injection Molding— introduces the principles of Decoupled Molding and the cavity pressure curves associated with such processes.

Read MoreInteractive Injection and Automation Display

Boy Machine will let users select a variety of trade fair giveaways to automatically fill a gift box molded at its stand.

Read MoreMelt Preparation Part 1: Melt Temperature Optimization

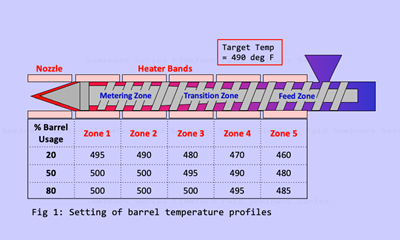

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series.

Read More