LIM & LSR Molding

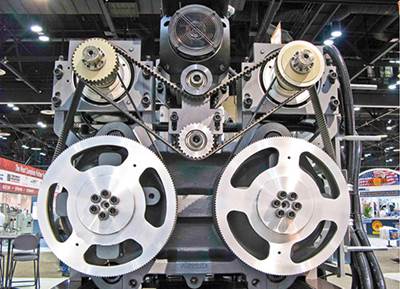

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

Read MoreUV Cure Solves LSR Processing Challenges

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreTightening the Screws on Precision Molding Of Thermoplastics & LSR

Fairly consistent focus of annual conference was how to get better control of the molding process.

Read MorePolyOne Acquires ColorMatrix

In late December, PolyOne Corp., Cleveland, completed the acquisition of ColorMatrix Group, Inc., Berea, Ohio, a maker of liquid colors and dosing equipment, colorants and additives for fluoropolymers, and specialty additives for PET and other resins.

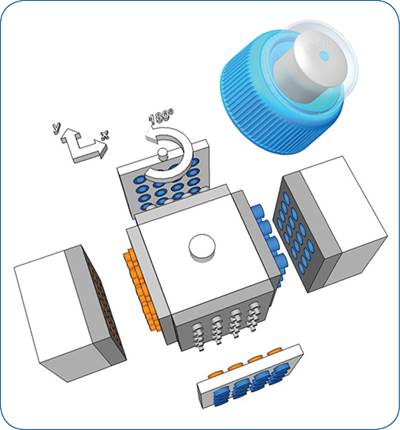

Read MoreGetting Into LSR--Part IV: How LSR Tooling Is Different

Building molds for rubber molding, and specifically liquid silicone (LSR ) injection, can be very challenging.

Read MoreLSR Part III-- Choosing a Mixing/Metering System

Liquid silicone rubber (LSR ) is a two component reactive chemical with a viscous, paste-like consistency.

Read MoreAutomation & Waste Reduction: A Medical Molder's Efficiency

Vision Technical Molding in Manchester, Conn., doesn’t believe in standing still.

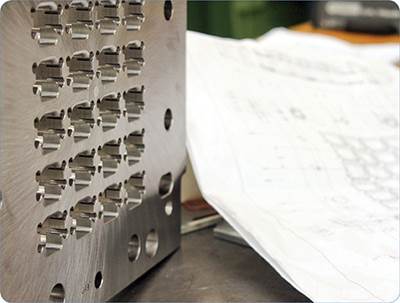

Read MoreMicro Molder & Mold Maker Succeeds by Specializing

How small is small? How small is micro? How about parts weighing as little as 0.00012 g and measuring no more than 0.038 in. (1 mm) long?

Read More