Purging Compounds

Purging Compound for High-Temperature Engineering Resins

Stable at up to 750 F, Slide’s new Hi-Temp Purge is ideal for purging PPS, PEEK, PET, LCP and PEI.

Read More'Highly Efficient' Purging Agent for Blow Molding Polyolefins

Techmer PM’s PFM117632 purging agent said to slash changeover time and offer significant sustainability benefits.

Read MorePurging Compounds for Thin-Wall Polyolefin Packaging Production

Chem-Trend’s new series of UltraPurge 100X boasts high efficiency for purging thin-wall polyolefin packaging.

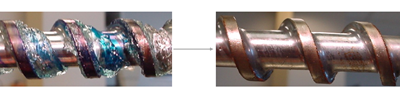

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read MoreSun Plastech Has Rebranded to Asahi Kasei Asaclean Americas

Company believes the new brand emphasizes the technical expertise and global product development focus for which Asahi Kasei is so well known.

Read MoreMaterials: Purge and Shut-Down Masterbatches for Polyolefins

Ampacet’s new additions to its line of purge and shut-down concentrates are aimed at maintaining product quality and cutting costs,

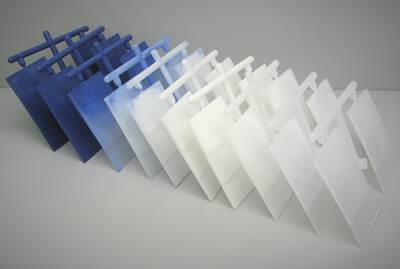

Read MoreSingle-Dose Purge Compound Yields Big Savings for Molder

Blackhawk Molding switched to premeasured packets of a new purge compound for 63% overall cost savings.

Read MoreFully-Operational Asaclean-Sun Plastech Provides Free Online & Phone Technical Support

Responding to coronavirus market challenges, Asaclean offers essential businesses and other plastics processors free technical & product support.

Read MoreBe Proactive in Your Purging Program

True, it can be tough to take a machine out of production, but a purging maintenance program should be thought of as a direct line to cost savings.

Read MoreTry This Lower-Cost Purging Method

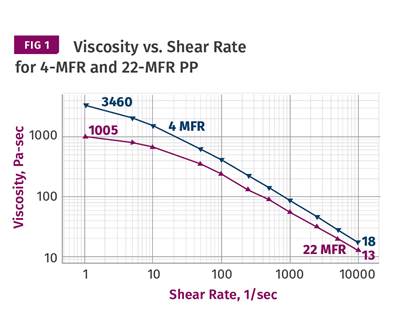

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read More