screws

Extreme Coatings Names Jackson Director, North American Sales

Company also extends its global manufacturing footprint.

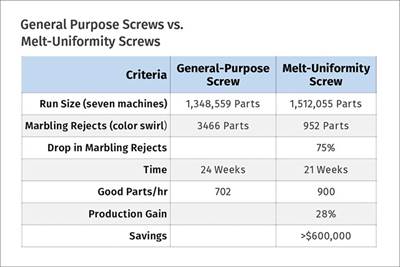

Read MoreImprove Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreXaloy Invests in New R&D Center

Xaloy is investing in a new R&D Facility for plasticizing equipment in northeast Ohio with aid from JobsOhio R&D Center Grant.

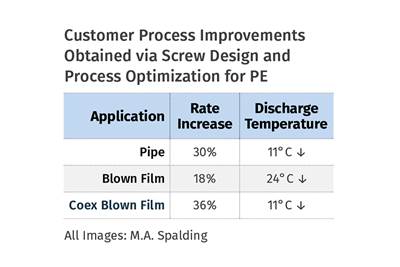

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

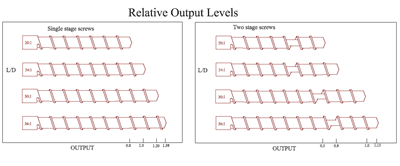

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreImprove Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

Read MoreXaloy to Reopen Virginia Manufacturing Facility

The Pulaski site was closed in 2016 by former owner Nordson, which consolidated screw and barrel operations in Ohio

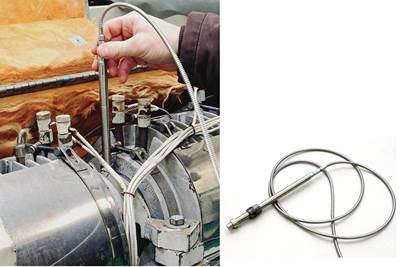

Read MoreTake the Guesswork Out of Determining Screw, Barrel Wear

New technology from Glycon takes real-time measurements of screw and barrel wear and provides data to guide processors as to when the time may be right to swap out these components.

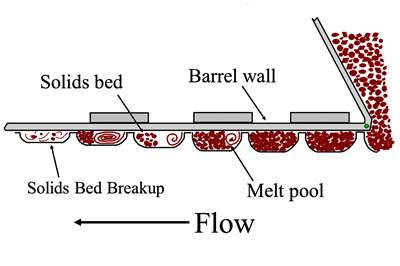

Read MoreNew Technology Opens a Predictive Window Onto Screw Wear

Despite their integral role in transforming pellets fed through the hopper into parts ejected from the mold, visibility into the performance, health and efficiency of screws is difficult to discern for many reasons, not the least of which being the fact they’re located inside a barrel.

Read MoreNordson Selling Screw, Barrel Business

Private equity firm Altair expects to close on acquisition during the first quarter of next year.

Read More