screws

Injection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreSizing the Barrier Gap

Here’s a less complex way to properly size the barrier gap for barrier screws.

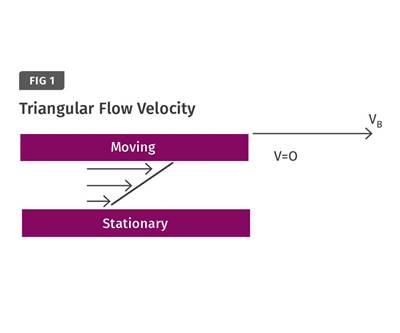

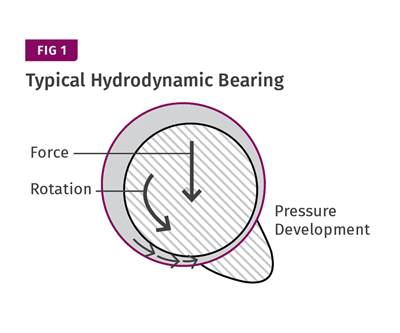

Read MoreHow ‘Hydro Wedges’ Reduce Screw Wear

Using them only in the melting section provides for greater design freedom and negates the impact these devices can have on output and melt temperature.

Read MoreK 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

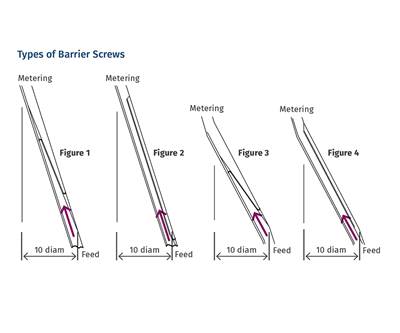

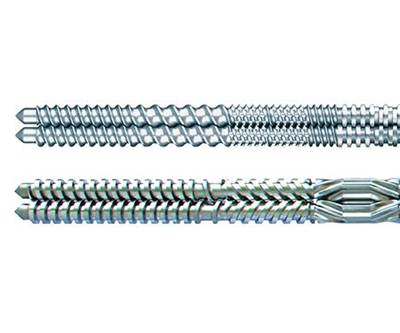

Read MoreWhich Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

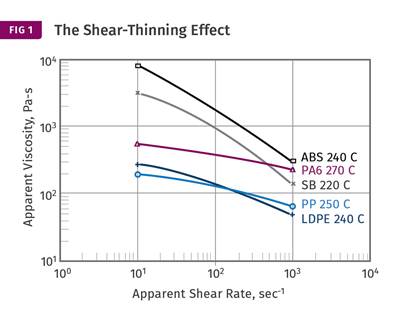

Read MoreWhat Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

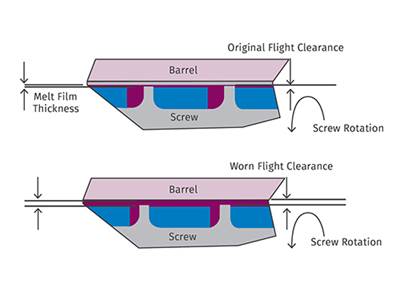

Read MoreDo You Have Screw Wear?

It’s generally caused by metal-to-metal contact, and your first indicator will be poor melt quality.

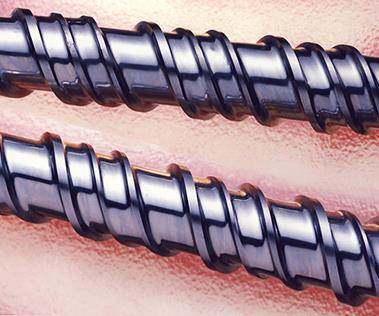

Read MoreGet Better at Swapping Out Your Twin-Screw Elements

Here’s what you need to know to safely and efficiently remove, clean, restage, and reinstall your twin-screw extruder screw set.

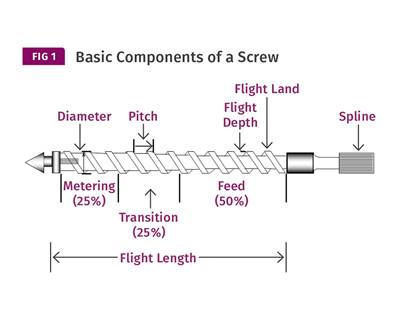

Read MoreEXTRUSION: Finding the Sweet Spot in Screw Design

The compression ratio of a screw does not provide enough detail on how it will perform. Screw design is a balancing act that takes many variables into account.

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

Read More