screws

Partner Sought for Commercialization of "Revolutionary" Extruder for Recycling

The cylindrical extruder developed by VTT could revolutionize processing of recyclable materials including plastics, textiles and food waste.

Read MoreExtrusion: Compact Extruder Is Potent, Energy Efficient

Small-footprint machine reportedly uses up to 95% less energy/lb of material processed and can typically achieve dimensionally stable product within 20 min. of being turned on.

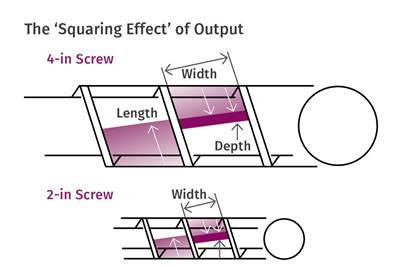

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

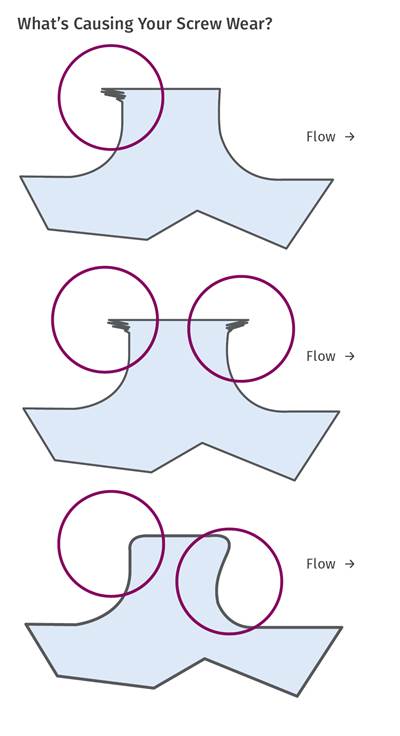

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

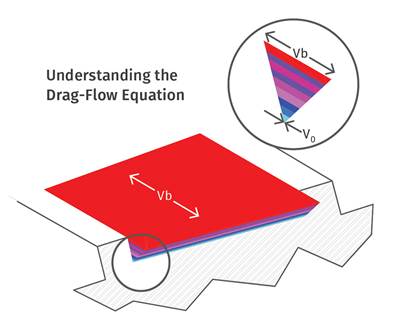

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

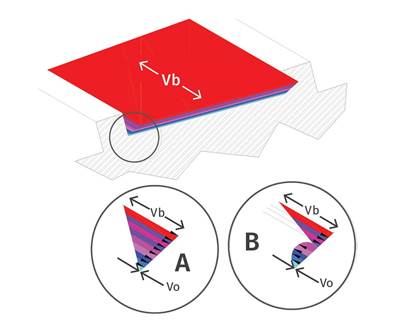

Read MoreExtrusion: A Simple Way to Evaluate Extruder Screws

While there’s lots of data that influences screw design, processors usually don’t have access to it. So instead, try calculating drag flow to see if your screw is working properly.

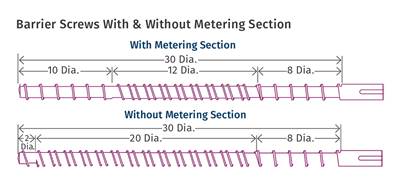

Read MoreExtrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

Read MoreWhat is Your Extruder Trying to Tell You?

Being in tune with your film extrusion equipment will allow you to identify issues before they start impacting production.

Read MoreExtrusion: The Role of Polymer Density in Screw Design

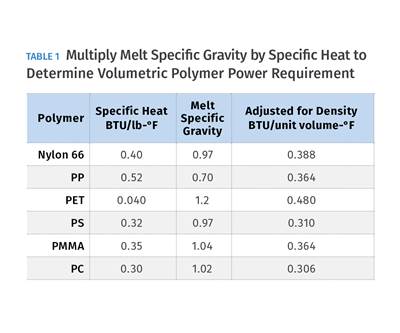

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

Read More