screws

Try a ‘Complete’ Method to Clean Screws, Barrels

Pulling the screw will give you direct access to clean all surfaces. Here’s how to do so in an efficient, safe, and non-destructive way.

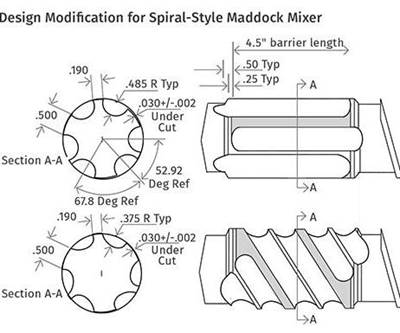

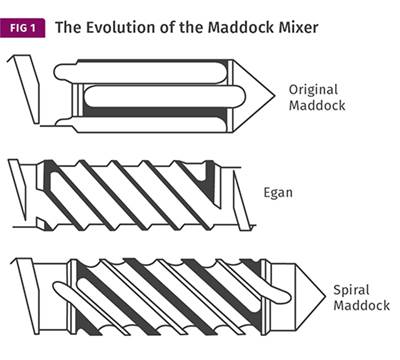

Read MoreEXTRUSION: Venerable Maddock Mixer Still an Extrusion Workhorse

Variations to this decades-old mixing section are widely used, but processors should carefully analyze these designs and not assume they will perform better.

Read MoreNovel Coating Dramatically Extends Life of CPVC Screws

Molding parts of CPVC require Hayward Industries to re-coat its screws every 12 months. Now, thanks to a unique screw coating, it’s at eight years and counting.

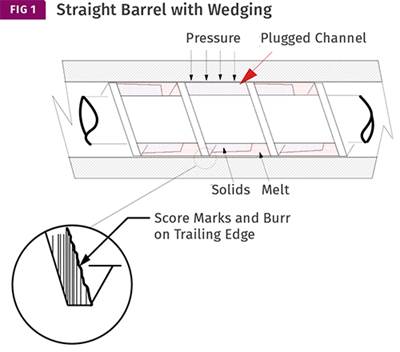

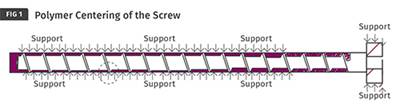

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

Read MoreEXTRUSION: Barrier Screws and Mixers

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

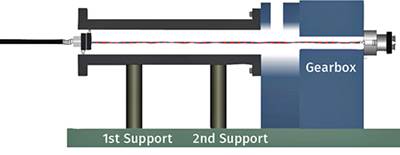

Read MoreKeep Extruder Barrels Aligned…And Production on Target

A misaligned barrel causes a lot of trouble. Laser alignment is being used now to keep things on the straight and narrow.

Read MoreA Very Small World: Micromolding at Makuta

Makuta Technics sweats the tiny details so it can run ‘lights out’ most of the day.

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

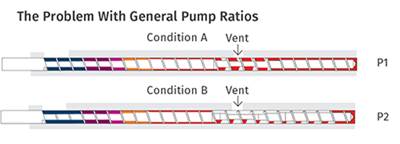

Read MoreEXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

Read More