Stretch Blow Molding

Blow Molding: Faster, Super-Compact PET Blow-Fill-Cap System for Still Water

Sidel’s new Super Combi Compact is 30% faster and occupies 30% less floorspace.

Read MoreNovel PET Water Bottle Pushes ‘Eco-Friendly’ Boundaries

Sidel’s AYA offers super-light weight, 100% rPET content, and reduction of secondary and tertiary packaging materials.

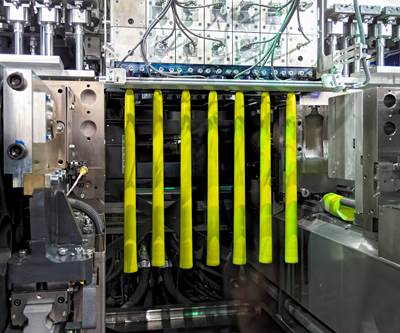

Read MoreInjection Molding: Lubricant Coating Keeps PET Preforms Scratch-Free

Prevent scratching of PET preforms during bulk packaging and handling with a new system for spraying a lubricant coating on the preforms.

Read MoreLighter Weight & PCR Content in Multi-Trip PET Bottles

Refillable PET bottles are a significant factor in Mexico and parts of Latin America, as well as in Germany. This development combines 15% lightweighting with 35% recycle content.

Read MoreSpring-Water Bottler to Expand In-House PET Recycling

Two California bottling plants are producing Crystal Geyser spring water bottles with at least 50% rPET now. Soon, the company plans to be using 100% rPET in all seven of its U.S. plants.

Read MorePretium Packaging Expands PET Blow Molding

Based in Chesterfield, Mo., Pretium Packaging has invested $5 million in PET stretch-blow molding equipment and infrastructure at six of its 19 manufacturing locations in the U.S. and Canada.

Read MoreHoneywell Debuts Aclar Edge Barrier Bottles for Pharmaceuticals

Honeywell has expanded beyond Aclar barrier films into Aclar Edge barrier bottles for pharmaceuticals and other moisture- and oxygen-sensitive products.

Read MoreR&D/Leverage in Stretch-Blow Tooling Alliance with Aoki

A domestic source for tool design, build and repair for Aoki injection stretch-blow molding machines.

Read MoreCoronavirus Doubles Demand for Used Blow Molding Machines

Demand for hand sanitizer, alcohol, cleaning products and beverages is reportedly straining capacity in blow molding.

Read MoreHow Graham Packaging Counters PCR Supply/Demand Squeeze

Customers want more PCR—including food grade—than recyclers can supply. Solutions involve efforts to educate customers, employees, and the community at large. New technologies also offer hope.

Read More