technology in action

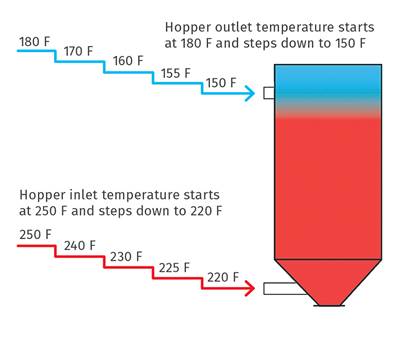

Technology Takes Aim At Drying Specialized Resins

Novatec develops new at-the-press drying solutions for molders tackling highly tailored nylons and other specialty materials.

Read MoreAir-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

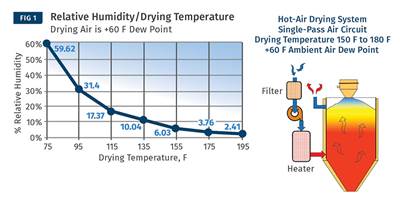

Read MoreWhy Drying Polyolefins Might Be Right for Your Process

From a technical standpoint, drying non-hygroscopic materials such as polyethylene and polypropylene may not be necessary. However, doing so may be advantageous to your process. Here are details.

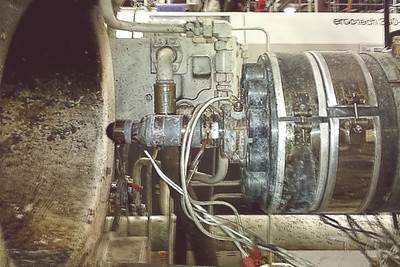

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

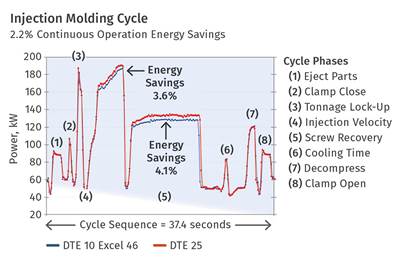

Read MoreSwitching Hydraulic Oil Saves Energy & Machine Downtime

Test at leading molder shows a high-viscosity, zinc-free oil improves pump efficiency and runs longer, cleaner, and quieter.

Read MoreThermoformer Chooses Clarified PP For New Food Containers

Lacerta expands beyond PET to offer one of the first clear PP packages with tamper-evident properties.

Read MoreSuccess Through Process Diversity

From heavy-gauge to light, and from the medical industry to the transportation market, Brentwood utilizes its wide range of thermoforming capabilities and expertise to engage customers around the world.

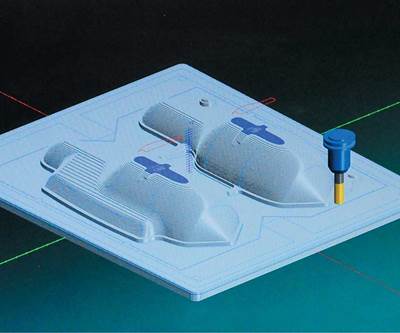

Read MoreCAM Adds Agility to Custom Thermoformer

CNC machining permeates ATI’s business, making its operations more efficient and responsive.

Read MoreHigh-Tech Blow Molding At Agri-Industrial Plastics

This family-owned custom molder stands out in its use of advanced computer and automation tools to claim a niche in large, complex, and multi-layer parts.

Read MoreFormer Has a Full-Blown Focus on Sustainability

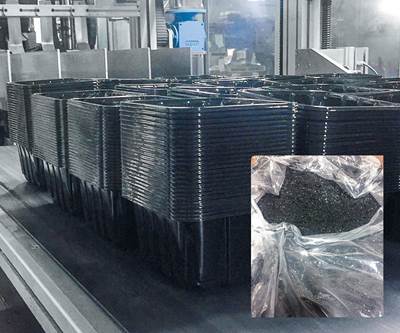

Shepherd Thermoforming’s operation has spared millions of PET bottles from death by landfill. It also has taken steps to slash its own energy and water consumption.

Read More