technology in action

Metal/Plastic Hybrid Molding: Flexible Alternatives for Teletronics

In overmolding of plastic onto electronic components, the goal today is flexibility. Here are three real-world examples of different kinds of modular cell layouts that have been used in production.

Read MoreGW Plastics Bets on Metal 3D Printing

Conformal cooling is goal of big investment at U.S. mold facility.

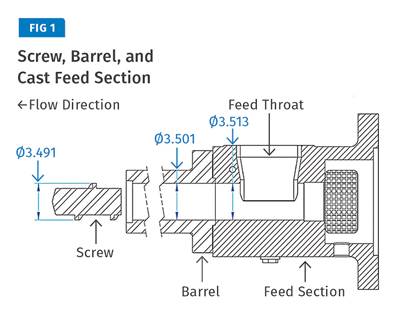

Read MoreCast vs. Integral: Which Feed Section Is Best for You?

Here are seven factors extrusion processors should weigh to help them decide between cast feed section versus an integral extrusion feed section.

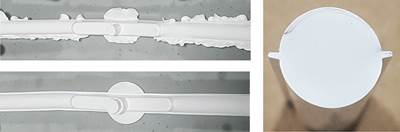

Read MoreTooling: Hot Sprues—Mold a Disk or Not?

Having a hot sprue shut off against the parting line versus intentionally molding a thin disk has been the subject of controversy for many years.

Read MoreNovel ‘Flat’ Fiberglass Enhances Injection Molded TP Composites

Advances in fiberglass reinforcements for thermoplastics have evolved from conventional chopped strand to long-glass fibers to hybrids of long glass and carbon fibers.

Read MoreNow You Can Injection Mold Unpainted Automotive Soft Skins

New S-TPE for interior trim challenges slush molding and TPV competition.

Read MoreVacuum Drying Sucks Wasted Time From Process Set-Up

A switch to vacuum drying resulted in a completely revamped process for this custom molder.

Read MoreFollow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreNew Engineering Materials for Challenging Automotive Applications

Nylons, PPA, and PPS for high heat and chemical resistance and/or high strength with light weight.

Read MoreCobot Helps Molder Keep Pace

Collaborative robot boosts process efficiency by 25%, while unburdening workers from the shop floor’s more tedious tasks.

Watch