Tooling

Bonanza of Hot Runners & Controls Introduced at K 2010 Show

At the world’s largest plastics show in Dusseldorf last fall, hot-runner and controller manufacturers introduced a flood of new developments in speed, size, accuracy, and reliability.

Read MoreTOOLING: Standard Components and In-Mold Monitor at K 2010

K 2010 news in tooling aims at helping injection moldmakers speed product to market.

Read MoreTooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

Read MoreTips and Techniques: Break the Taboo On Purging Hot Runners!

It’s safe to say that the concept of using a commercial purging compound (CPC) has largely been embraced by the plastics processing community.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

Read MoreLargest Aluminum Injection Mold Ever

Unique Tool & Gauge, Windsor, Ont. (unique-tool.com), completed a production injection mold machined from the largest block of tooling-grade aluminum ever forged.

Read MoreTips and Techniques: Mold Filling Analysis Now You Can Adapt Injection Mold Filling Simulation for MuCell

While mold-filling simulation is a very common tool for predicting the fill patterns of an injection mold, in our judgment there is not yet a commercially available, satisfactory filling simulation for microcellular foam molding.

Read MoreK 2010- Injection Molding New All-Electrics & Hybrids Balance Performance & Economy

The world’s largest plastics show, coming up next month in Dusseldorf, Germany, provides ample evidence of the growing sway of electric drive technology in injection molding.

Read MoreTooling: Setting Up a Mold Shop: Part I

I had a toolmaker once tell me he used to slam his hand in his car door before work every morning just to get him in the right frame of mind to work in his shop.

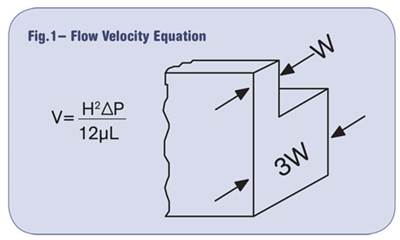

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read More