Tooling

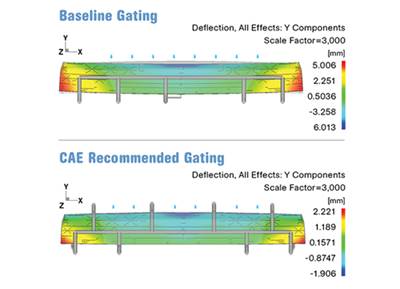

Tier 1 Automotive Molder Uses Team Approach to Mold Simulation

SRG Global calls in outside assistance to solve a tricky technical problem.

Read MoreNew Way to Characterize Moldability Of Resins & Part/Tool Designs

Experienced injection molders have long known that a resin’s melt flow index (MFI), measured under very low-shear conditions, provides very little information about how it will process under many orders of magnitude higher shear in an actual mold.

Read MoreMold-Masters Gains Exclusive Use Of Ritemp Technology for Hot Runners

Hot-runner supplier Mold-Masters Ltd., Georgetown, Ont., has obtained rights to exclusive global use of Ritemp evaporative cooling technology for hot-runner molds.

Read MoreCures for Common Hot-Runner Wiring Problems

In the challenging environment of the last several years, manufacturers are looking inward to improve their manufacturing processes, streamline their supply chains, lower maintenance costs, andimprove their bottom lines.

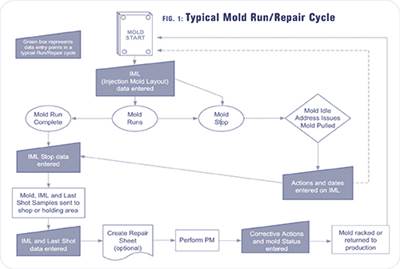

Read MoreThe Value of 20 Bits of Data

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

Read MoreTooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

Read MoreSafety Sense in the Shop

Running a clean, organized, professional, and safe shop requires a team effort that includes an awareness of unsafe practices and equipment that need to be eliminated, replaced, or improved, along with the accountability of all to identify and document safety issues.

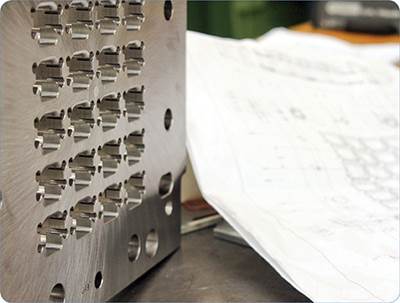

Read MoreGetting Into LSR--Part IV: How LSR Tooling Is Different

Building molds for rubber molding, and specifically liquid silicone (LSR ) injection, can be very challenging.

Read MoreWhy Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read More