Engineering Resins

Engineering resins are a category of polymers typically used in more demanding applications than commodity resins. They typically have properties that offer higher performance such heat, chemical, and impact strength resistance which makes them well suited to replacement of metals and other materials in a wide range of electrical/electronic, automotive, aerospace, medical, and industrial applications. They include volume engineering resins ABS, PC, and nylons 6 and 66, as well as PBT, PEEK, PPO, PPS, higher-temperature nylons such as PPAs (polyphthalamides), POM, and LCPs.

ESSENTIAL READING

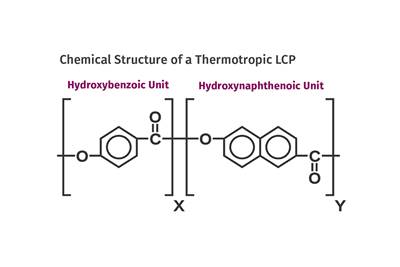

VIEW ALLTracing the History of Polymeric Materials, Part 28: Making LCP's Melt Processable

Liquid-crystal polymers based on a single monomer produces a polymer with a very high melting point.This presents two problems. Here’s how they were solved.

Read MoreTracing the History of Polymeric Materials, Part 27: Liquid-Crystal Polymers

Liquid-crystal polymers debuted in the mid-1980s, but the history of the chemistry associated with this class of materials actually starts a century earlier.

Read MoreTracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

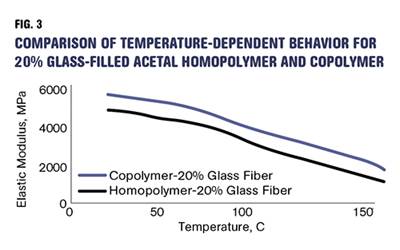

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

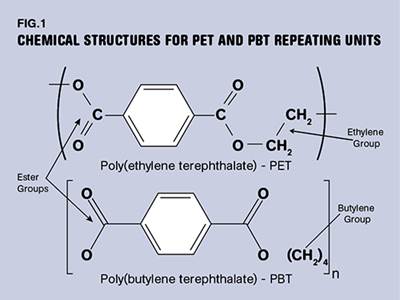

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide Blends

PPO was a promising new high-performance thermoplastic, but it could be made useful only by mixing it with a humble commodity resin.

Read MoreLatest Engineering Resins News And Updates

Ineos Lustran 532 ABS Tailored for Furniture Edging

New ABS grade offers processability, medium gloss, and stable color base for self-coloring, tailored for furniture edge bands.

Read MoreSABIC Opens Ultem Resin Manufacturing Facility in Singapore to Meet Asia-Pacific Demand

Facility will produce ULTEM for technology applications.

Read MoreINEOS Styrolution to Close ABS Production in Addyston, Ohio

Company will commence a safe and responsible decommissioning process in the second quarter of 2025.

Read MoreBiomass Content TPUs Reduce Carbon Footprint

Lubrizol Advanced Materials is introducing four new grades.

Read MoreHigh-Performance PPA for Next-Generation IGBT Semiconductors

BASF’s Ultramid Advanced N3U42 G6 is tailored to enhance robustness, long-term performance and reliability.

Read MoreNew Short Cellulose Fiber-Reinforced Acetal Grades

Polyplastics’ new Duracon POM grades offer performance benefits over glass-reinforced POM and lower environmental impact.

Read MoreFeatured Posts

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreGeneral Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

Read MoreTeknor Apex Presents Daily Hourly Sessions on Broad Range of Materials for Sustainability and Electrification

NPE 2024: Teknor Apex discusses its recyclable thermoplastic elastomers and much more between Tuesday and Thursday

Read MoreAsahi Kasei Showing Engineered Plastics Including Recycled PP and Nylon, 3D Printing Filaments, and Asaclean Plus Purging Concentrate

NPE2024: Xyron and Thermylene engineered resins include recycled versions and new 3D printing filaments highlighted, as well as Asaclean Plus purging concentrate.

Read MoreResin Distributor Poised for Recycling and Electrification Trends

NPE2024: Chase Plastics offers a portfolio that includes its own sustainable brand CP Pryme Eco.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreFAQ: Engineering Resins

Lower mold temperatures and the associated faster cooling rates produce higher levels of internal stress in the molded part. This arises in part because of the more rapid development of the frozen layer as the material flows into the mold. This can result in flow lines that are visual evidence of impeded flow. It also produces a higher degree of retained orientation in the more rapidly cooled layers at the exterior surface.