Articles

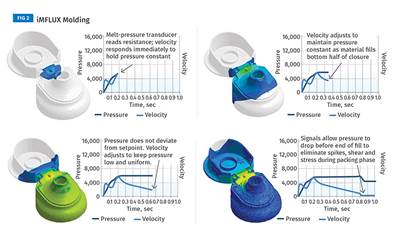

A New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

Read MoreGet into the Zone: 3D/4D Printing

Expect to see exhibitors representing three countries and a range of industries, from automotive to healthcare and everything in between, all putting on display the wide variety of uses for 3D/4D printing in today’s rapidly digitalizing world. Here visitors will see the technologies enabling many companies to produce prototypes, mold components, and even finished parts directly from digital files.

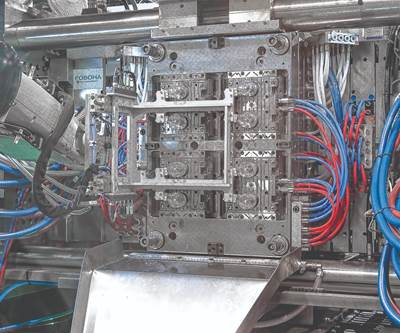

Read MoreGet into the Zone: Moldmaking

One of the largest zones at NPE2018, the Moldmaking Zone features the latest technology in moldmaking and brings together professionals from across the field of manufacturing. According to Glenn Anderson, Chairman of NPE2018 and V.P., Strategic Account Development for Milacron, attendees and exhibitors should expect to see a little of everything in this zone.

Read MoreTechnology Is the Solution For This Compounder

Compounding Solutions has seen its business grow by 20% in each of the last 12 years. That’s no accident. The firm has become a mainstay supplier of compounds—primarily for medical—by tapping into its expertise in technology and processing.

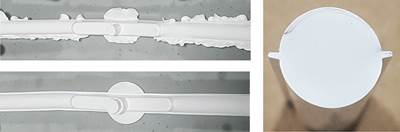

Read MoreTooling: Hot Sprues—Mold a Disk or Not?

Having a hot sprue shut off against the parting line versus intentionally molding a thin disk has been the subject of controversy for many years.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

Read MoreCold Pressed-In Threaded Inserts: An Economical Alternative

Cold pressed-in threaded inserts provide a sturdy and cost-effective alternative to heat staking or ultrasonically installed threaded inserts. Discover the advantages and see it in action here. (Sponsored Content)

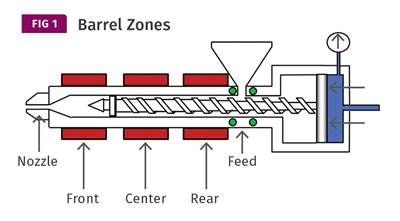

Read MoreInjection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreA Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreNovel ‘Flat’ Fiberglass Enhances Injection Molded TP Composites

Advances in fiberglass reinforcements for thermoplastics have evolved from conventional chopped strand to long-glass fibers to hybrids of long glass and carbon fibers.

Read MoreNow You Can Injection Mold Unpainted Automotive Soft Skins

New S-TPE for interior trim challenges slush molding and TPV competition.

Read MoreUnique Machine Combines Dryer, TCU in Single Footprint

Novel, space-saving device co-developed by Novatec and Advantage Engineering offers a single control designed to reduce setup mistakes.

Read More