Articles

Cincinnati Inc. and Oak Ridge Nat'l Lab Partner On Large-Part Additive Mfg.

It is becoming much more frequent these days that we are alerted to yet another new development in additive manufacturing/3D printing.

Read MoreChinaplas 2014 shows its green side

Traditional Chinese culture has five standard colors—green, red, yellow, white and black—which were associated with the elements of wood, fire, earth, metal and water, respectively.

Read MorePrices Up, Except for PP

Prices of PE, PS and PVC were on the way up last month, while PP prices could be headed in the other direction.

Read MoreAdditive Manufacturing: Materials for ‘Real-World’ Parts

Developments in materials have helped pave the way for processors to make ‘real world’ parts from what is collectively known as 3D printing. Here’s a comprehensive review of the materials available.

Read MoreThe ‘Total Package’ in Thermoforming

Here's how a leading edge custom former evolved from a CAD/CAM business.

Read MoreUse Your Gauge to Solve Processing Issues Upstream

Gauging systems have an often-overlooked but equally important role beyond measuring web thickness: They can be used as a diagnostic tool to troubleshoot the process. Here's how.

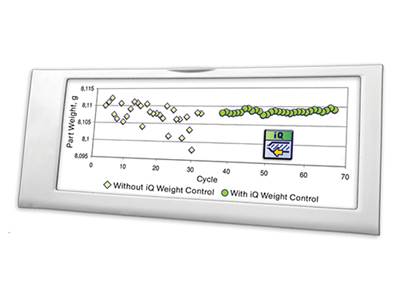

Read MoreSwitch Over To Consistent Quality

A new process-control method picks up variations in melt quality and viscosity during the injection phase and equalizes them within the same shot.

Read MoreThe Truth About Reshoring

Reshoring is not just a buzzword, it’s an economically driven correction to a supply chain that had become unbalanced.

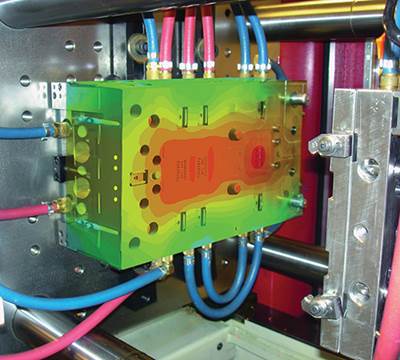

Read MoreNews in Molding Simulation at K 2013 Show

At October's K 2013, suppliers of injection molding simulation software displayed solutions addressing a number of hot topics, as well as technology to speed up handling of larger models and multiple iterations.

Read MoreFive-Layer Line Gives Processor More Flexibility, New Opportunities

Processor bumps it up from three-layers to boost quality, flexibility and enter new markets.

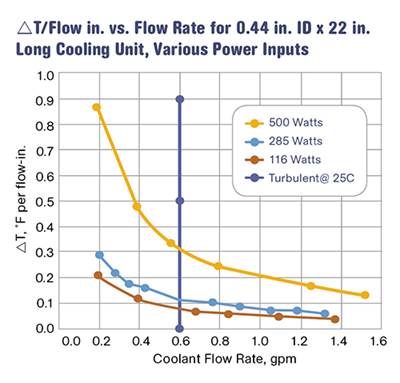

Read MoreLeverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

Read MoreExtruding High-Temperature Resins

Older extrusion lines might not be suitable for processing materials up to 750 F. Here's what you need to know to get started.

Read More