Automation

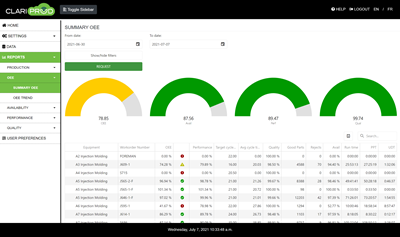

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

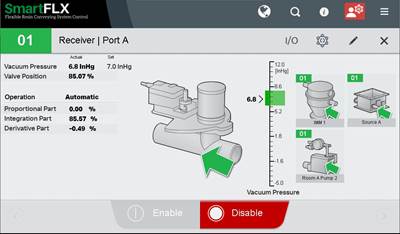

Read MoreConveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreFaster Top-Entry Model Among 19 Robots in Orlando

NPE2024: Sepro Group is introducing the newest S5-25 Speed robot, promising 63% faster acceleration, as one of 19 robots on display at its booth and partner booths at the show.

Read MoreDirect Communication, Control Between Cobots and IMMs

NPE2024: Universal Robot is showing how its Injection Molding Machine Interface (IMMI) module facilitates direct communication and control between its robots and molding machines.

Read MoreSix-Axis Top-Entry Robot Debuts

NPE2024: Absolute Robot will debut the MaxCW10-1600A+B+C 6-axis top entry robot, featuring additional axes and updated control, as well as a Fanuc cobot automating a vertical press.

Read MoreRobotic Sorters With AI Technology Deployed in Fresno Recycling Center

A grant from the Recycling Partnership enabled Implementation of RecycleOS Technology from Everest Labs.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreResearch Project Probes Potential for AI-based Sorting in Postconsumer Polypropylene

Process couples vision-based sorting with efficient decontamination to separate high-value PP.

Read MoreQuickly Change Robotic End-of-Arm-Tools by Hand

ATI’s patent-pending MC-50 manual tool changer enables quick changes of robotic end-of-arm tools (EOAT) by hand.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Watch