best practices

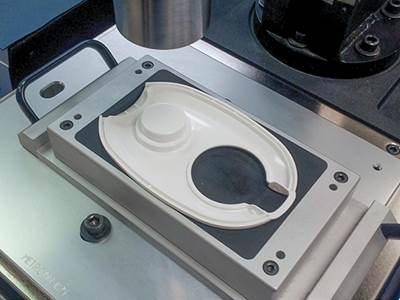

Servo Welder Gives Molder More Control

Applications that require near-hermetic seals are now easily achieved by this electronic contract manufacturer.

Read MoreHow to Mold Long Fiber Reinforced Thermoplastics

Here’s the machinery, tooling, and process know how you need to get the most out of these high-performance materials.

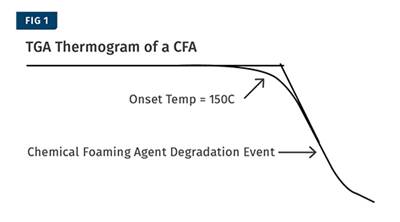

Read MoreHow Characterizing and Modeling Chemical Foaming Agents Can Help Your Process

Knowing ahead of time what will happen when your CFA produces gas can help you design or improve your process to boost quality and cost effectiveness.

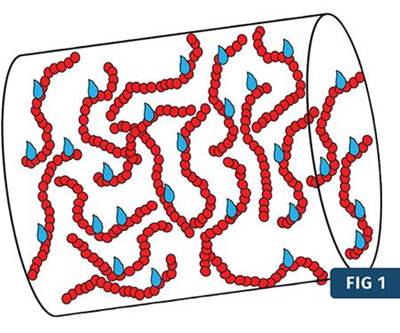

Read MoreOvercome Typical Challenges in LSR Molding

Here’s a quick overview of basic mold and machine factors behind common LSR molding headaches and how to avoid them.

Read MoreHow to Dry PET for Container Applications

PET is extremely hygroscopic, highly moisture sensitive, and one of the toughest challenges to dry. Here are the basic principles of doing it right for rigid packaging applications

Read MoreOn Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreWhy Processors Are Rediscovering Liquid Colorants

In extrusion, injection, and blow molding, liquid color is enjoying something of a renaissance. Cost is one reason, but advances in pigments, carriers, delivery systems, and innovative service programs have played a role too.

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

Read MoreHow to Address Uneven Wall Thickness in Stretch-Blow Molding

Many conditions must be met to get the best wall distribution in a PET bottle. Skilled operators are, as always, indispensable.

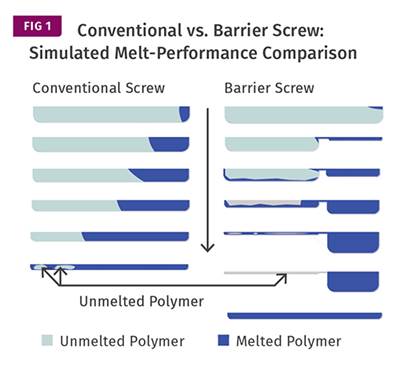

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read More