best practices

Reduce Hot-Runner Downtime With Proper Troubleshooting

Solve your problem faster by adopting a systematic approach. Here’s how to get going.

Read MoreB&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

Read MoreRFID Boosts Production Efficiency For Bumper Molder

RFID technology significantly improves ‘error-proofing’ and productivity from molding to final fabrication.

Read MoreSwitch to AC Drives & Save Energy, Maintenance Costs

Smaller, cooler AC packages can be retrofitted to existing lines to slash energy use and maintenance costs.

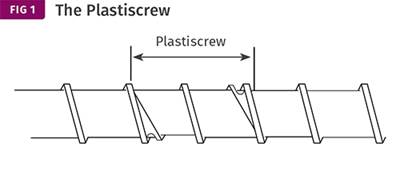

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

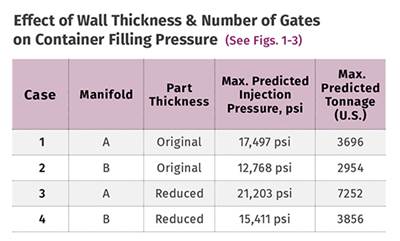

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreMATERIALS: Don’t Guess Your Way Through Root Cause Analysis

More than 50 different polymer test techniques can be used to find root causes of problems. Of these, five or six are fairly common. Use them to take the guesswork out of why a product failed.

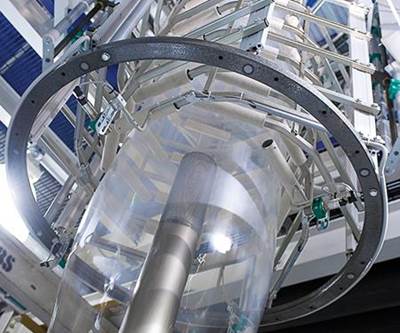

Read MoreFollow These Tips to Clean Your Blown Film System

Proper purging procedures can avoid the need to shut down the line for cleaning. Here's one expert's advice.

Read MoreHow to Avoid Problems When Using Commercial Purging Compounds

The best approach is to implement and standardize a three-step program to ensure you are purging in the best and most cost-effective manner possible.

Read MoreMEDICAL MOLDING: Configure Your Molding Machine Into a ‘Clean Room’

You can meet the stringent requirements of the medical market without having to invest in a full-blown production clean room.

Read More