best practices

Injection Molding, California Style

There are particular challenges associated with plastics processing in the Golden State. But opportunities beckon for those who can overcome them. That’s the story of AMA Plastics.

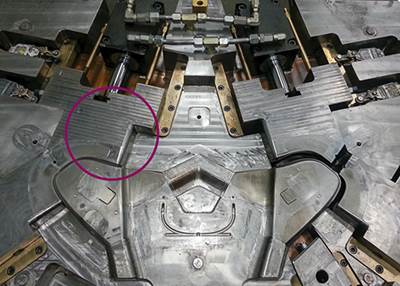

Read MoreTOOLING: Venting: A View From the Trenches

Venting is a prime culprit for molding problems, partly because toolmakers and process techs have different ideas of what’s needed.

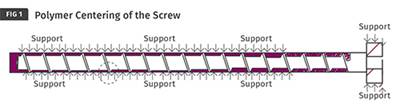

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

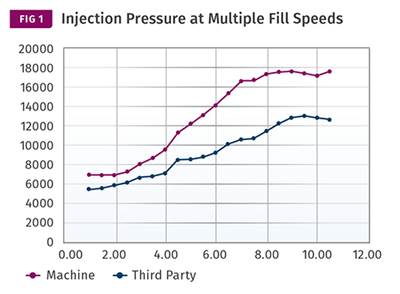

Read MoreINJECTION MOLDING: Scientific Molding Gone Wrong

Sometimes molders get trained in Scientific Molding only to revert to their old way of doing things as soon problems pop up.

Read MoreMATERIALS: The Trouble with Data Sheets

Data sheets are routinely relied upon, yet the data they provide is limited in scope and can lead to incorrect conclusions.

Read MoreFive Steps Toward a Flawless Flat Film Start-Up

A poor line start-up benefits no one … except your competitors. Follow these five steps to get your film line fired up seamlessly.

Read MoreGet the Most Bang For Your Purging Buck

More processors are turning to purging compounds to clean their machines and speed up changeovers. Here are tips on how to avoid typical trouble spots when using them.

Read MoreWhen Robots Make Sense For Part Packaging

Here are nine issues to take into account before automating your end-of-the-line part-packaging process.

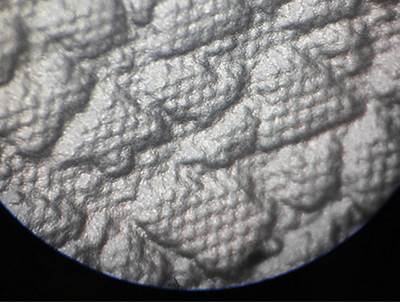

Read MoreTOOLING: Clearing Up the Mysteries Of Mold Texture

It’s a subject not widely understood by molders and it affects more than just part appearance.

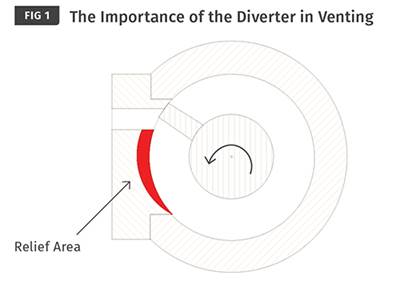

Read MoreExtrusion: What’s the Best Way to Vent?

There are advantages and disadvantages to each, and they must be evaluated before making a decision.

Read More