dies

Internally Cooled Pipe Die Speeds Output, Reduces Stresses

The recently developed Internal Air Cooling Die from iBA GmbH in Germany substantially increases output of polyolefin pipe or correspondingly reduces the length of downstream cooling, the company says.

Read MoreStop Die Buildup

Die buildup, also called die drool, die bleed, or plate-out, can plague any extrusion process.

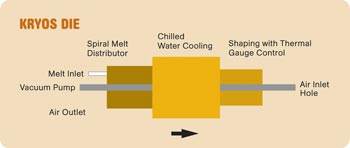

Read MoreAir/Water Cooling Die Doubles Output of PE Pipe

A new high-output extrusion die for large HDPE or PP pipe (110 to 2000 mm OD) combines water-cooling of the melt before it leaves the die with air cooling inside the pipe.

Read MoreTemperature Control Modules

The Shini USA Industrial Temperature Control Modules, utilized primarily for injection Molding, Extrusion, Die-Casting among others are off the shelf, built for top performance and are ideally suited for all plant environments and industrial processes.

Read MoreStop Die-Hole Freeze Off

Custom compounders use underwater pelletizers for a growing range of engineering polymers, including resins like PET, nylon, and polycarbonate that exhibit such “difficult” characteristics as low viscosity and/or rapid cooling or high melt temperature.

Read MoreMoving Die Parts Change Profile Shapes 'On the Fly'

Change one tubing lumen into two, or two lumens into three, or even split one tube into two in a “Y” shape: These are some of the dramatic alterations that can be made “on the fly” with a novel articulated die concept available for license from Specialty Silicone Fabricators, a medical tubing maker in Paso Robles, Calif.

Read More9-Layer Leading Edge Blown Film Technology

With a trend towards more and more layers, die manufacturers face a number of challenges.

Read MoreW&H's MAXICONE Minimizes Changeover Time with Compact Die Design

MAXICONE, the 5- to 7-layer die launched by W&H is making the grade in customer satisfaction, with reports of reduced changeover times upwards of 80% on the many systems sold and installed in the field.

Read MoreNo. 46 - Auto Gauge Control For Flat Dies

Automatic thickness control of slot dies for cast film and sheet began in the 1960s.

Read MoreNo. 44 - Spiral Dies For Pipe and Blown Film

Spiral dies were the answer to removing knit lines from spider dies.

Read More