dies

Best Practices for Cleaning a Flat Die and Technologies for Molding Hollow Parts

Learn step-by-step procedures to thoroughly clean a flat die and technologies for injection molding of hollow parts.

Read MoreSheet Extrusion Line

A sheet extrusion line consists of an Extruder (single or twin screw), equipped with a Screen Changer and a Gear Pump, followed by a Static Mixer (sometimes feeding a Coextrusion Feedblock that is preceded by one or more additional extruders sets as described above), feeding a flat sheet die.

Read MoreFollow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

Read MoreExtrusion: Start Up and Shut Down Properly

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read MoreYour Extruder's Best Friend

That's the melt pump, and its main purpose is to precisely control output to the die.

Read MoreHow United Plastics Became A Quick-Change Artist

United Plastics Corp., a small profile and sheet extruder with 125 employees in Mount Airy, N.C., combines an almost unbelievably diverse product mix (it has some 5000 dies in active use) with the ability to change over individual extrusion lines four or five times a day.

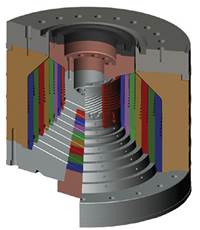

Read MoreCommunication Is Key in Designing Blown Film Dies

Over the years I have bought, designed, or helped design quite a number of blown film dies.

Read MoreTooling Know-How: Five Tips on Profile Die Design

A poorly designed profile die—one that does not permit the part to be extruded with the same dimensions from run to run—coupled with a lack of understanding of the extrusion process, is a recipe for scrap generation.

Read More