Film Extrusion

Tooling: More Is Better…Layers, That Is

I can’t count the number of times I have been asked why I recommend a blown film line with 5+ layers to make 2- or 3-layer products.

Read MoreEXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

Read MoreK 2010 Preview, Extrusion More…Layers, Output & Quality

In most segments of extrusion technology, the word at K 2010 is more.

Read MoreBoosting Extrusion Productivity-Part II of III: Optimize Product Changeover & Purging

Extrusion processors typically run a number of different products and resins.

Read MoreSolving the Puzzle of Chinese Bags

How do the Chinese get such high quality at such low cost? They have been accused of dumping, but Chinese bag makers are mostly small mom-and-pop businesses that survive on razor-thin profit margins. Their plants and the way they run them are like nothing you’ve ever seen.

Read MoreExtrusion at NPE 2003

NPE is typically a competitive display of the biggest, most dramatic equipment machine builders can muster.

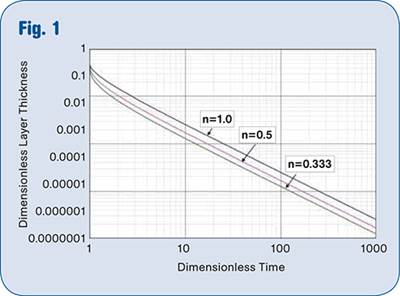

Read MoreMelt Fracture or Interfacial Instability? Different Ills Needs Different Cures

In blown film, clarity is often considered synonymous with quality.

Read MoreA Family Film Business Goes High-Tech

Papa, as Norman Rabenstein is fondly called on the shop floor, brought his family up to make plastic film.

Read MoreModest Investment, Big Payoff For Blown Film Plant

In blown film, there is certainly more than one way to skin a cat.

Read MoreFilm Extruder Tries Do-It-Yourself Electric Power

One of the country’s largest makers of stretch film and bags, the Sigma Plastics Group based in Lyndhurst, N.J., has embarked on an experiment in generating its own electricity.

Read More