Film Extrusion

NPE News in Extrusion

This NPE show won’t have a lot of extruders on the floor, either running or static. Instead, look for videos and announcements of new technology. You will also find lots of ingenious peripheral devices to improve output and quality and save resin. Some will do all three, and cost less into the bargain.

Read MoreANTEC at NPE: Editors' Picks

One of the unusual features of NPE 2009 in Chicago June 22-24 will be the first-ever concurrent presentation of the SPE ANTEC conference, by far the largest of seven conferences at McCormick Place during the show.

Read MoreNPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

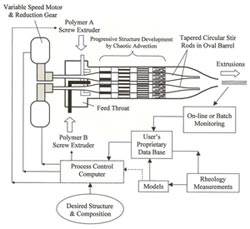

Read MoreNovel Melt Blending Technology Commercialized in Micro- and Nanolayer Films

The first two commercial devices have been installed to melt blend two or more polymers using a structured fluid-dynamic mixing process known as “chaotic advection.” This process creates unusual micro-scale and nano-scale phase morphologies that potentially can optimize extruded film properties using fewer materials and extruders than with highly layered coextrusion.

Read MoreGloucester Engineering Teams Up With Kabra in India

Gloucester Engineering Co. in Gloucester, Mass., has formed a joint venture with Kolsite Group in Mumbai, India, to build blown film lines at Kabra Extrusiontechnik Ltd., a Kolsite company.

Read MoreShining Opportunities In Solar Films

Photovoltaic markets are growing explosively, and so are opportunities for specialty film producers. Solar cell and module production, which was forecasted to grow at 50% a year for the next few years before the recession hit, is now expecting slightly more healthy 30% annual growth, according to DuPont, a major supplier of photovoltaic film materials. Solar cell and module manufacturers are expanding, and large numbers of new companies are entering the field.

Read MoreStop Die Buildup

Die buildup, also called die drool, die bleed, or plate-out, can plague any extrusion process.

Read MoreHigh-Speed Extrusion: Are You Ready for the Fast Lane?

Around three dozen, mostly European, processors are pushing commercial development of high-speed single-screw extrusion. They have installed more than 100 of the small hyper-drive machines whose screws turn at up to 1500 rpm, about eight to 10 times faster than standard extruders. At least two German machine builders are working on machines that will go to 2000 rpm and even higher. The goal is to raise output without increasing extruder size.

Read MoreDon’t Wind Wrinkles Into Your Film

Wrinkles are a major cause of defects in extrusion winding and converting, especially with thinner films, which are much more wrinkle-prone than thick ones. The cause of most wrinkles is located close to the roller where the wrinkle first appears and can be identified by looking at the orientation and pattern of the wrinkle. First, find the cause; then try to eliminate or at least reduce it.

Read MoreInvesting in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

Read More