Film Extrusion

New Die Opens Up New Markets

General Plastic Extrusions Corp. found that out recently in converting a second-hand blown film line that had been used by its previous owner for R&D.

Read MoreWhy—and How—to Baseline Your Extruder

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

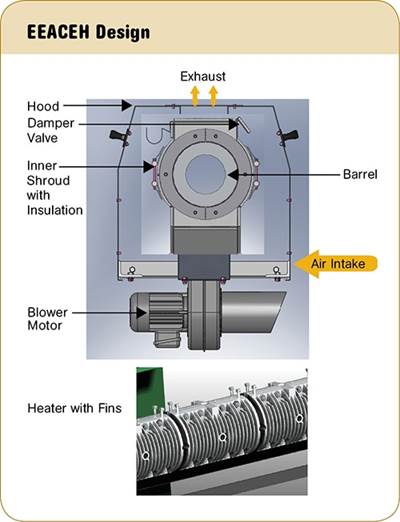

Read MoreNew Barrel Heater/Cooler Saves ‘Juice' to Run an Extruder

New, patent-pending design is said to reduce both radiant and convection heat losses.

Read MoreReport Details Opportunities for Battery-Film Processors

If you make battery separator films you might be interested in a report released recently by Eldib Engineering & Research, Berkeley Heights, N.J.

Read MoreDuPont Honors Packaging Innovators

Sixteen winners honored in 23rd annual awards ceremony.

Read MoreDetermining the Maximum Machine Direction Orientation (MDO) Possible for Sheet

Given a set film thickness, width and material, how to you determine how much machine-direction orientation (MDO) is possible for a sheet.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

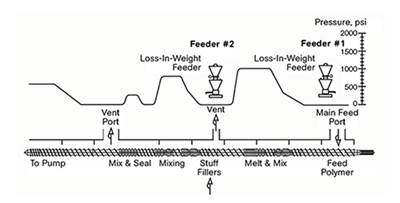

Read MoreLook Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

Read MoreMaximum Head Pressures for Extruders and Choosing the Best Melt-Filtration Tech

What is the maximum head pressure an extruder should run at and how do you choose which melt-filtration method is best for your application?

Read More