Injection Molding

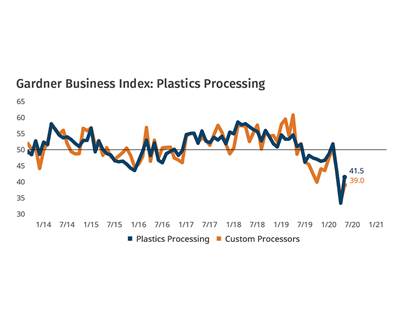

Contraction Slows for Processors

For the first time since the coronavirus pandemic, Gardner Business Index signals decelerating contraction as all components report improved readings.

Read MoreHow to Properly Maintain Aluminum Injection Molds

Aluminum and steel tools have some important differences, but also one key similarity: Routine maintenance will extend the mold’s life and boost the quality of its output.

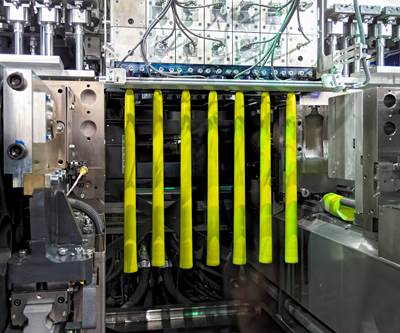

Read MoreRJG Training Facility Adds Bole Machine

RJG’s Gibsonville, N.C. training site has added a 110-ton servodriven hydraulic Bole consignment machine.

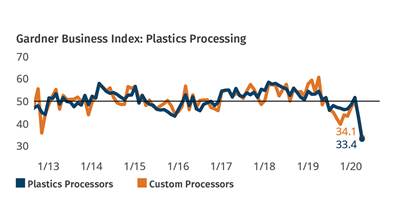

Read MorePlastics Processing Business Continued Contracting in April

Global economic shutdown causes downturn in new orders and production.

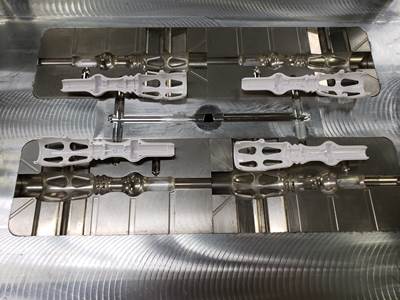

Read MoreTooling: How to Properly Size Gates, Runners and Sprues, Part 4

How to get the sprue, runner and gate sizes close to ideal the first time around.

Read MoreAttention Moldmakers: Amerimold Goes Live

Live and on-demand sessions, exhibitor showrooms, a community forum and more—Amerimold is online June 9-13, register now for free.

Read MoreCoronavirus Doubles Demand for Used Blow Molding Machines

Demand for hand sanitizer, alcohol, cleaning products and beverages is reportedly straining capacity in blow molding.

Read MoreSimulation Software Speeds Mask Development

Sigma Engineering partnered with Arburg and others to expedite the design and optimization of a molded LSR mask, using simulation to determine mold setup, filling calculations and thermal layout in 24 hours.

Read MoreFundamentals of Proper Press Shutdown

Press shutdown procedures have a significant impact on achieving smooth machine startups and restarts to improve uptime. Here’s a procedure you might want to deploy in your molding operation.

Read MoreMilacron Announces Rental Options for New Machinery

Plastics processing machinery supplier Milacron introduced a new rental option for its equipment via an exclusive financing partner, Equipment Finance Group (EFG), granting emergency capacity to serve Covid-19 projects.

Read More