Materials Know How

Tracing the History of Polymeric Materials: Polyphenylene Oxide Blends

PPO was a promising new high-performance thermoplastic, but it could be made useful only by mixing it with a humble commodity resin.

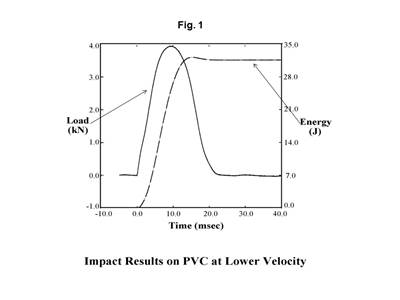

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

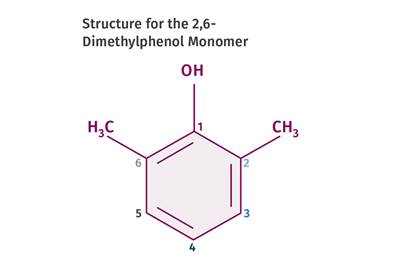

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide

Behind the scenes of the discovery of PPO.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

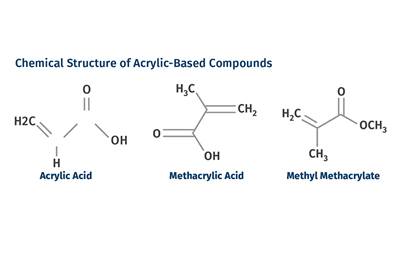

Read MoreTracing the History of Polymeric Materials: The Commercialization of Acrylic

We covered the invention of acrylic in our last installment. Here, we discuss its commercial development.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

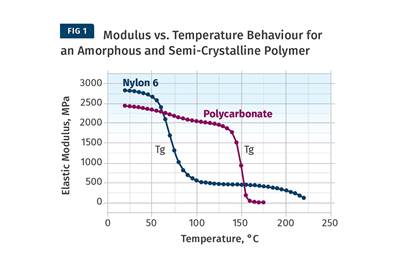

Read MoreThe Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

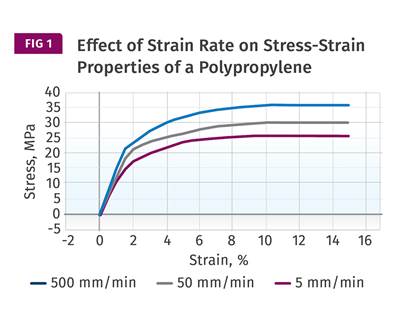

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

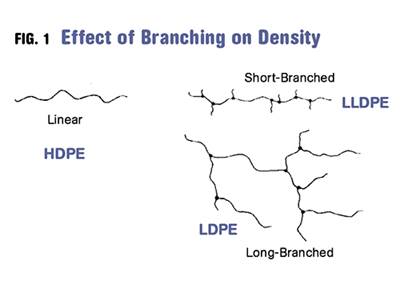

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read More