Materials Know How

Materials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

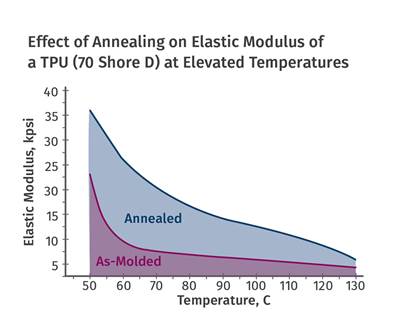

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

Read MoreMaterials Part 5: Annealing Tips for Crosslinked Polymers

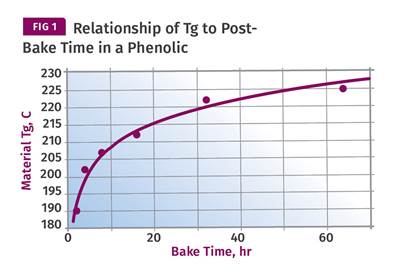

As with semi-crystalline thermoplastics, annealing can be used in thermosetting polymers to obtain a level of crosslinking that may not be possible within the molding cycle.

Read MoreMaterials: Annealing Tips for Semi-Crystalline Polymers: Part 4

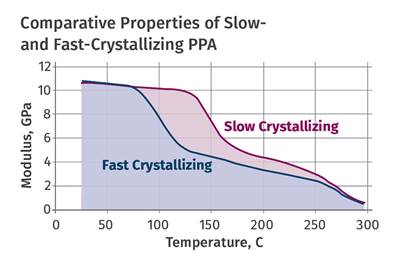

You can forgo the elevated mold temperatures normally recommended for high-performance semi-crystalline materials. But it’s risky and likely to yield parts that under-perform expectations … assuming that they emerge from the annealing process looking anything like the drawing.

Read MorePart 3 Materials: Annealing Tips for Semicrystalline Polymers

For these polymers, annealing is done to establish a level of crystallinity that cannot be practically obtained within the parameters of a normal molding cycle. Here’s some guidance on setting annealing time and temperature.

Read MoreMaterials: Annealing Tips for Amorphous Polymers, Part 2

In amorphous polymers, annealing is performed to draw down the internal stresses to a level not achievable within the conditions of a normal molding process. But a few parameters are important to achieving the desired results.

Read MoreMaterials Part 1: What Annealing Can Do for Your Process

Relatively rapid cooling rates in processing introduce internal stress. If functional problems in use result, annealing may draw down the stress to levels that may not be achievable during processing.

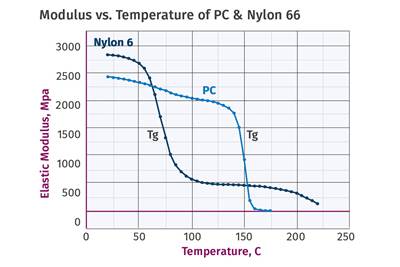

Read MorePART 2: The Importance of Mold Temperature When Processing Polycarbonate

Don’t be afraid to increase mold temperature to improve part quality when making PC parts. Take a look at a few examples here.

Read MorePart 1: The Importance of Mold Temperature When Processing Polycarbonate

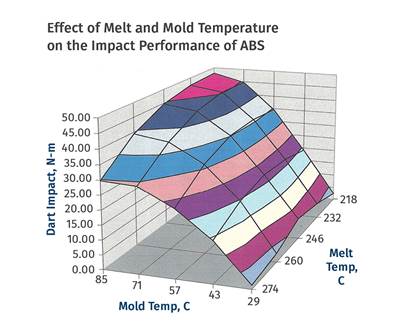

An often overlooked factor in optimizing the ductility of PC is the rate at which the polymer is cooled in the mold.

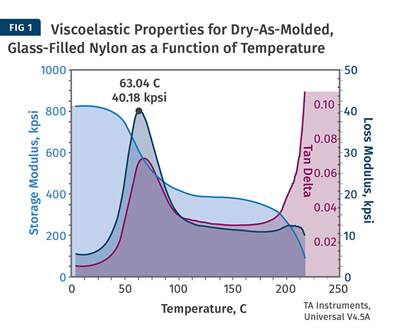

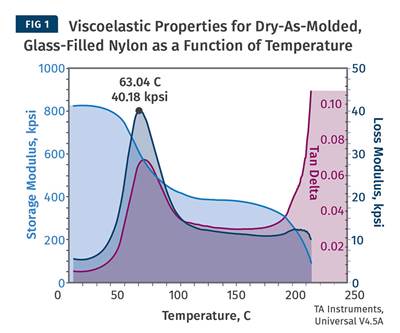

Read MorePart 5: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

In the final part of this five-installment series, we bring DMA to a practical level using the results for glass-filled nylon.

Read MorePart 4: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

The presentation of DMA data can sometimes frustrate users and discourage its adoption. Those unfamiliar with DMA should insist on receiving data relevant to the manner in which the part they are developing will be used.

Read More