Materials Know How

Heat Deflection Temperature vs. Dynamic Mechanical Analysis (Part 3)

DMA provides a rich and detailed picture of polymer performance, and it can be challenging to understand all the things that we can and should know about our materials. But the fact that it may be hard does not mean that it should not be attempted.

Read MorePART 2 Heat Deflection Temperature vs. Dynamic Mechanical Analysis

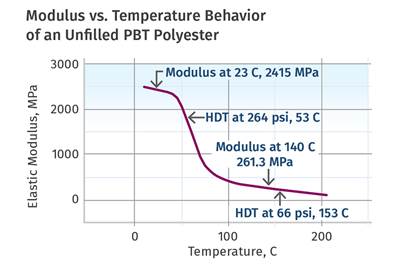

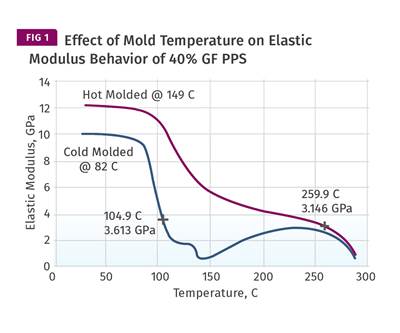

Here’s a real-world example of a part failure demonstrating why DMA curves have more value than single-point data generated by HDT.

Read MorePart 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

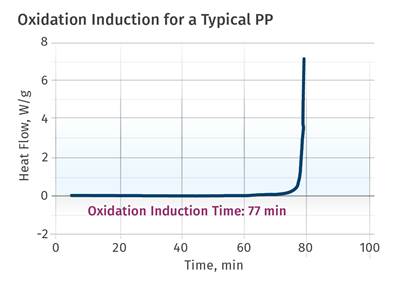

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreA Processor’s Most Important Job, Part 10: Fiber-Length Retention

Glass and carbon fibers are often used to increase material strength and modulus. To maintain these properties, the aspect ratio of these fibers must be maintained.

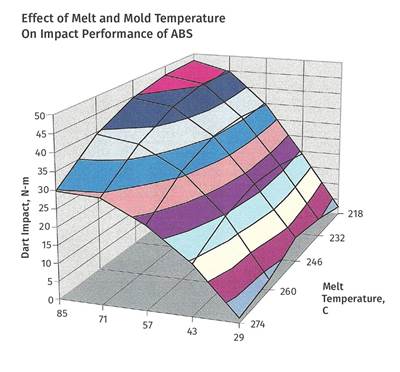

Read MoreA Processor's Most Important Job, Part 9: Avoid Molded-In Stress

How to establish molding conditions that minimize internal stress in a part.

Read MoreA Processor’s Most Important Job, Part 8: Molded-In Stress

How processing adjustments can control molded-in stress.

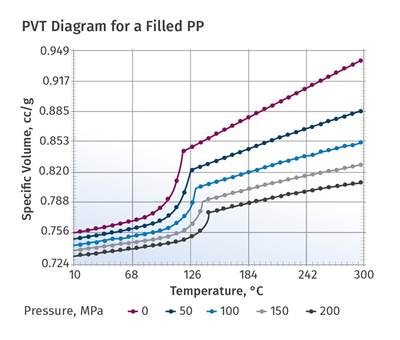

Read MoreA Processor's Most Important Job, Part 7: Reviewing Crystallinity

There are several process-related issues that influence crystallinity besides cooling rate. Let’s examine a few.

Read MoreA Processor's Most Important Job, Part 6: Long-Term Effects

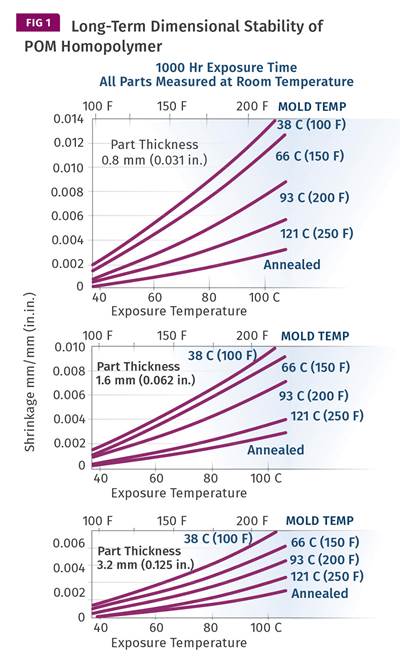

The importance of mold temperature to the development of the desired polymer crystalline structure becomes absolutely crucial in the case of high-performance materials.

Read MoreA Processor's Most Important Job, Part 5: POM Polymers

Using a mold temperature above a polymer’s Tg ensures a degree of crystallinity high enough to provide for dimensional stability, even if the part must be used at elevated temperatures. But POM is an exception. Why?

Read More