Testing

Testing in plastics can be done on the plant floor to improve quality in molded or extruded parts, and off-line in the lab not only to check if parts are up to specification but also to evaluate the quality of incoming raw materials.

ESSENTIAL READING

VIEW ALLHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreHow to Improve Quality with Offline Inspection and Analysis

Automated sample testing with a light table detects the smallest contamination in flakes, micro granulates and sample test sheets.

Read MoreHow to Create and Use Digital Color Standards for Plastics

Moving to a digital color workflow can help streamline production.

Read MoreTake These Steps to Optimize Your MFR Data

Make your life easier by paying close attention to the procedural steps detailed in the test standards.

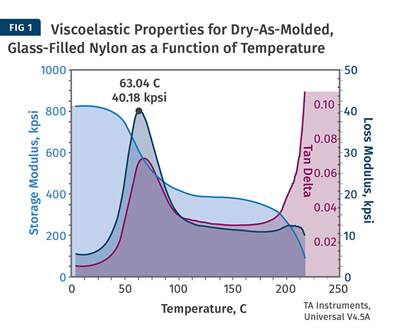

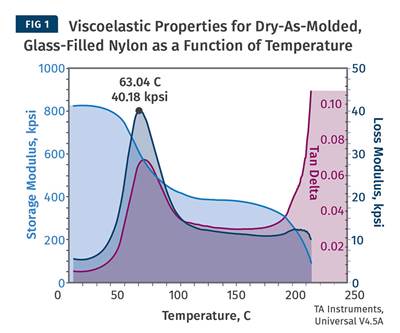

Read MorePart 5: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

In the final part of this five-installment series, we bring DMA to a practical level using the results for glass-filled nylon.

Read MorePart 4: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

The presentation of DMA data can sometimes frustrate users and discourage its adoption. Those unfamiliar with DMA should insist on receiving data relevant to the manner in which the part they are developing will be used.

Read MoreLatest Testing News And Updates

Measure Viscosity Precisely, Repeatably

NPE2024: The PVS viscometer from LAUDA Scientific is billed as the routine instrument for aggressive solvents in polymer chemistry.

Read MoreHeight Gauge With Added Features and Accuracy

NPE2024: Mitutoyo America’s LH600F features a touchscreen interface that enables easy and intuitive operation.

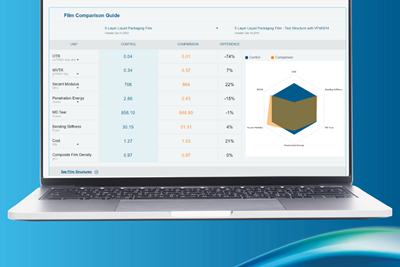

Read MoreUpdated Interactive Tool for Predicting Multilayer Film Performance

NPE 2024: NOVA Chemicals presents the latest enhancements to its Bonfire Multilayer Property Predictor and new Syndigo rPE portfolio

Read MoreUpgrade to Accelerated Artificial and Natural Weathering Testing

NPE2024: Atlas S³T system is designed for the company’s Weather-Ometer Ci4400 and Ci5000 instruments.

Read MoreSensors Measure Moisture in PVB Films, Pellets

NPE2024: Noncontact sensors provide a continuous, reliable reading with zero drift and no maintenance.

Read MorePowerful and Versatile Infrared Spectrometer

Thermo Fisher Scientific’s Nicolet Apex FTIR is well suited for a wide range of applications including materials analysis.

Read MoreFeatured Posts

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreHow Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreHow to Improve Quality with Offline Inspection and Analysis

Automated sample testing with a light table detects the smallest contamination in flakes, micro granulates and sample test sheets.

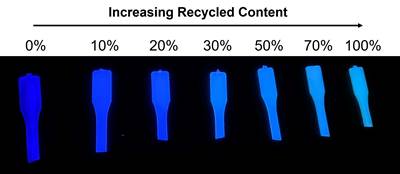

Read MoreFast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

Read MoreHow to Create and Use Digital Color Standards for Plastics

Moving to a digital color workflow can help streamline production.

Read MoreFAQ: Testing

How to optimize color evaluation of recycled plastics?

Whether for resins with PCR content or for virgin resins, the keys to minimizing variability in your color evaluation are to use the right color-measurement instrument (spectrophotometer—benchtop or hand-held) and to create good working methods, that is, establishing a standard operating procedure (SOP).

If you use an extrusion plastometer (melt indexer) to test the melt-flow rate (MFR) of resins, you can make your life a whole lot easier by paying close attention to the procedural steps detailed in the test standards, to ensure accuracy, efficiency and smooth operation. This is true whether you are conducting occasional tests or running extensive automated testing in a lab setting. Many say they meet a published test standard, but in reality they are not following the test standard exactly as written.

Testing Supplier Categories

- Other Testing/Analysis Equipment

- Air/water Pollution Analyzers

- Speed, Drive Controls

- Moisture Analyzers

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Technical and Trade Associations

- Thermal Analyzers

- Dielectric Cure Monitors

- Weathering Testers

- Physical/Mechanical Properties Testers

- Barrier Testing Equipment

- Coordinate Measuring Systems

- Flow Monitoring/Control Devices (for Liquids)

- Training Programs in Plastics

- Maintenance Management Systems

- R&D, Training Institutes

- Timers

- Pipe Thickness Measuring Equipment

- ISO 9000 Software

- Dewpoint Monitors/Moisture Analyzers

- Pressure Controllers, Monitors

- Temperature Controllers, Monitors

- Particle-Size Analyzers

- Electrical Properties Testers

- Materials Testing Services

- Film, Sheet, Coated Web Thickness Measuring Equipment

- Computer and Automation Testing Auxiliaries

- Color Matching/Formulating Systems

- Infrared Analyzers

- Temperature Pyrometers, Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Molded Parts Thickness Measuring Equipment

- Flame/Smoke Testers

- X-Ray Fluorescence Analyzers

- Screw Design/Analysis Software

- Leak Testers

- Titrators

- Sequence Logic Controls

- Chromatography Equipment

- Level Sensors and Controls

- Closed-loop Process Control Systems

- Gel Timers

- Machine Monitoring/Alarm Systems

- Acoustic Emission/Ultrasonic/X-Ray Flaw Detectors

- Profiles, Tubing, Wire Thickness Measuring Equipment

- Pressure Sensors, Transducers

- Rheometers, Viscometers, Melt Indexers