Articles

Ineos Styrolution Talks Closing the Loop on Polystyrene

The company is collaborating with several companies on several solutions, including depolymerization.

Read MoreFive Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

Read MoreRunning PCR? Optimize Performance & Processability with Stabilizers

Proper stabilization of PCR is vital to enable production of molded and extruded parts to meet brand-owner requirements.

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

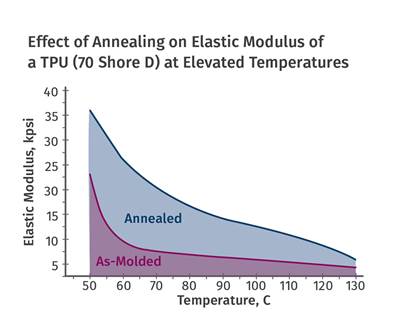

Read MoreMaterials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

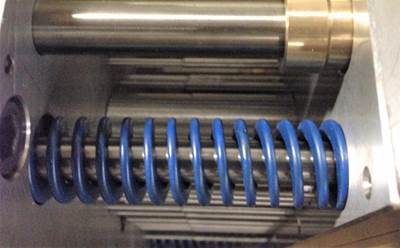

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read MoreTooling: Back to Basics On Die Springs--Part 2

Follow these steps for proper die-spring selection and installation.

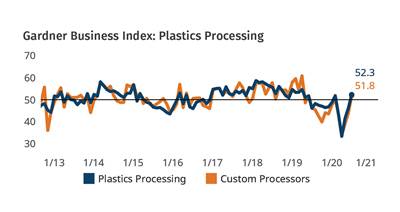

Read MorePlastics Processing Expands in July

With an Index reading of 52.3, processors report first monthly expansion since the coronavirus disruption.

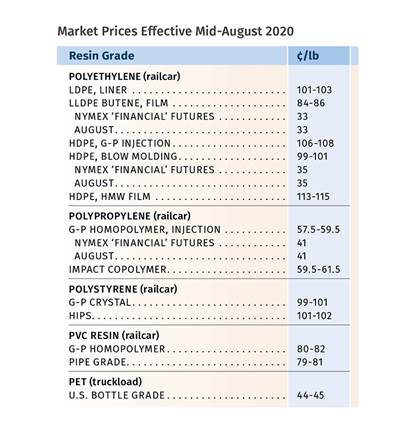

Read MorePrices Up for All Commodity Resins

Factors include strong domestic and/or export demand, tighter supplier inventories, and higher feedstock costs resulting from production outages.

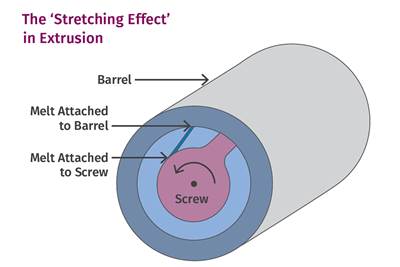

Read MoreExtrusion: Evaluating Screw Design for Multi-Material Recycling

Since many plastic products are made of a combination of materials with very different melting points, careful consideration must be given to designing screws when it comes time to recycle these products.

Read MoreHow and Where Twin-Screw Extruders Fit in Recycling

When utilized in a thoughtful way, the corotating intermeshing twin-screw extruder can transform recycled materials into value-added products and parts. Here’s what you need to know, and some real-world examples of the technology deployed for both post-industrial and post-consumer recycling.

Read MoreReactive Extrusion: Industry Icons Impart Their Insights

Three distinguished experts in the area of reactive extrusion shed some light on this process.

Read More