Articles

What You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read MoreNew PLA Molder Anticipates Swift Growth

SelfEco developed two diverse PLA product lines in less than a year.

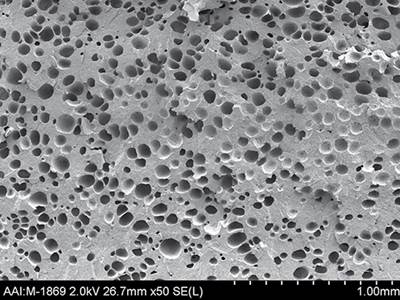

Read MoreTrexel Adds Chemical Foaming Agent to Its Product Line

Special additive offers economical microcellular foaming for low-volume jobs with PE, PP.

Read MoreR&D Thermoformer: Tek Pak Is Launch Pad For New Products

Toolmaker and thermoformer takes concepts to production-ready parts in record time.

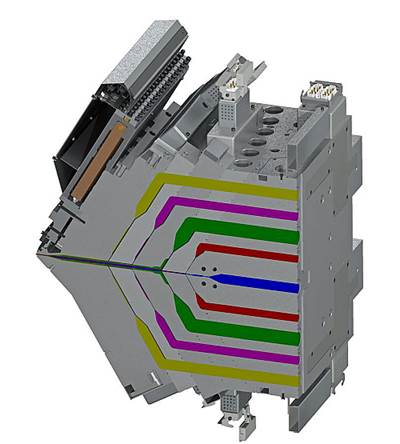

Read MoreWorld’s First Nine-Manifold Flat-Film Die Up and Running

Feedblock-free technology reportedly cuts thickness variations by two-thirds.

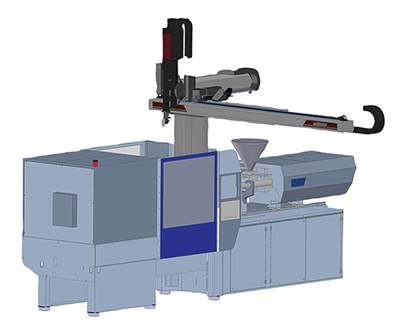

Read MoreSpec’ing a Robot? Match It To Your Press Size & Project

Where is your business today? What might tomorrow’s molding projects look like? These are among the questions you need to answer when deciding what style of robot is best for you.

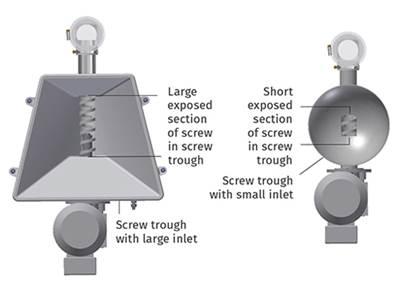

Read MoreTo Improve Feeder Performance, Start by Understanding Three Key Components

These are the screw trough, agitator, and the screw itself. It’s crucial to understand the different types and the advantages/disadvantages of each.

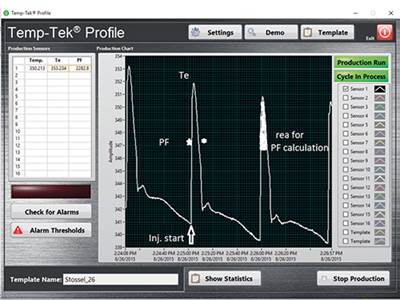

Read MoreNew Sensor Tech Monitors State of the Melt During Molding

Detect ‘true’ melt temperature, viscosity variations, melt density, and much more, throughout the molding cycle.

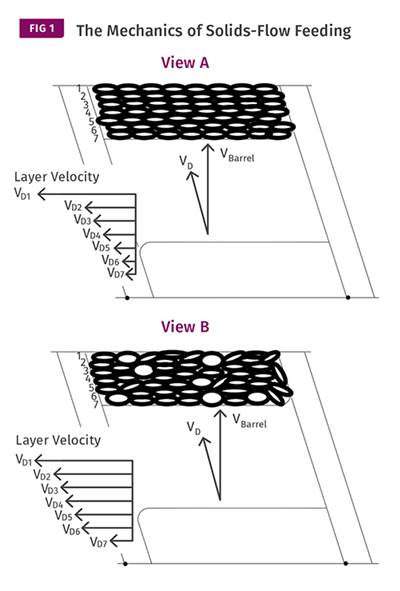

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

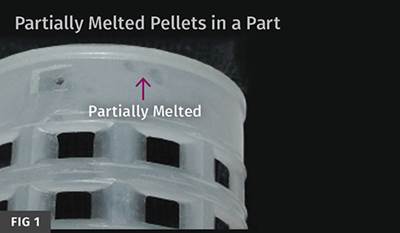

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

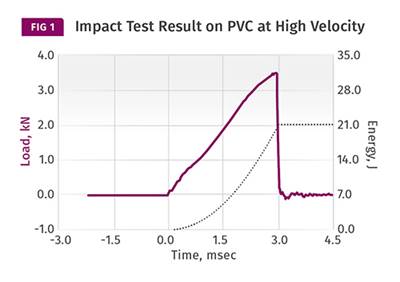

Read MoreMATERIALS: Impact Testing: The Problems With Single-Point Data

Knowledge of test conditions and graphical data showing the course of the impact event can help provide engineers and designers with the information they need to make informed choices about material toughness.

Read More