Molds & Tooling

Molder Takes 3D Printing In-House to Speed Product Development

“Bringing this function in-house is very much in keeping with the way our company conducts its business.

Read MoreOvercoming IML’s Challenges To Reap Its Rewards

In-mold labeling has advanced dramatically over the past 20 years, but mostly in Europe. Here is what you need to know to bring IML to your operation.

Read MoreDo You Still Get Stubborn Surface Defects, Even With Sequential Valve Gating?

Sequential valve gating either eliminates or greatly reduces the flow-front collisions, and resulting knit lines, between a set of nozzles. However, there are still applications using sequential molding where a “ghost mark” or marks occurs on the part between a set or pair of nozzles and/or near the gate itself.

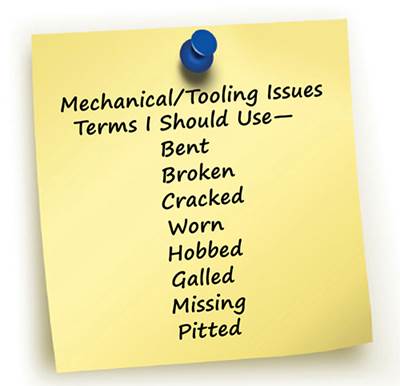

Read MoreMaintenance Terms of Endearment

Look closely at your company’s mold maintenance language and formalize your approach to create a clear and concise picture—one that can be measured.

Read MoreU.S. Medical Development Center For Ritemp Cooling Technology

Novel conformal cooling technology from Ritemp Pty.

Read MoreTOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

Read MoreBrand-New Test Method Relates Material, Mold & Machine

It's the first material characterization method developed specifically for evaluating the injection moldability of a plastic melt.

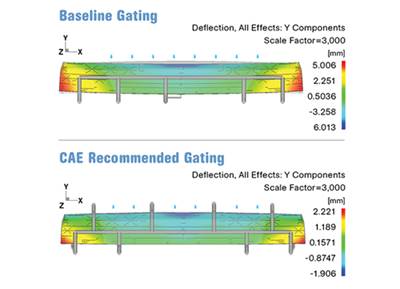

Read MoreTier 1 Automotive Molder Uses Team Approach to Mold Simulation

SRG Global calls in outside assistance to solve a tricky technical problem.

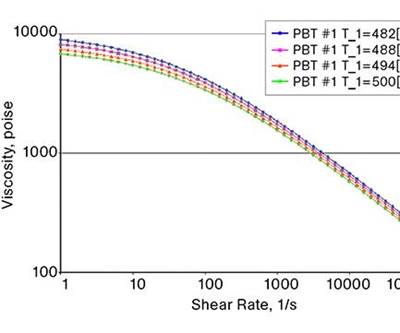

Read MoreNew Way to Characterize Moldability Of Resins & Part/Tool Designs

Experienced injection molders have long known that a resin’s melt flow index (MFI), measured under very low-shear conditions, provides very little information about how it will process under many orders of magnitude higher shear in an actual mold.

Read MoreMold-Masters Gains Exclusive Use Of Ritemp Technology for Hot Runners

Hot-runner supplier Mold-Masters Ltd., Georgetown, Ont., has obtained rights to exclusive global use of Ritemp evaporative cooling technology for hot-runner molds.

Read More