Molds & Tooling

Eight Steps Toward a Seamless Mold Transfer

It’s big news when an OEM decides to move a substantial number of molds from one processing operation (either their own in-house/captive facility or an outsourced molder) to another.

Read MoreNew Ownership for Husky

Boston-based private-equity firm Berkshire Partners and OMERS Private Equity of Toronto reportedly paid $2.1 billion last month to jointly buy Husky International Ltd. and its subsidiaries, which makes injection molding machines, hot runners and molds.

Read MoreCreate a Maintenance Work (Bench) Cell

Get better results by improving the organization of your mold-maintenance operation.

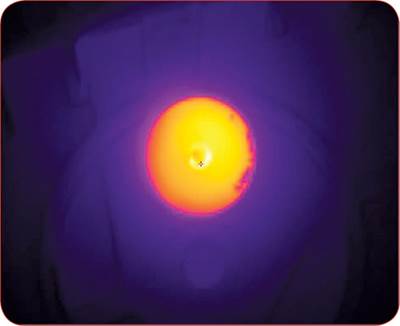

Read MoreTaking the Temperature of Mold Productivity

Increasing traffic in transfer tooling from molders that have shuttered operations or are unable to successfully produce parts is driving interest in a long-established but under-utilized diagnostic technique for injection molding.

Read MorePay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreTOOLING: Standard Components and In-Mold Monitor at K 2010

K 2010 news in tooling aims at helping injection moldmakers speed product to market.

Read MoreTooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

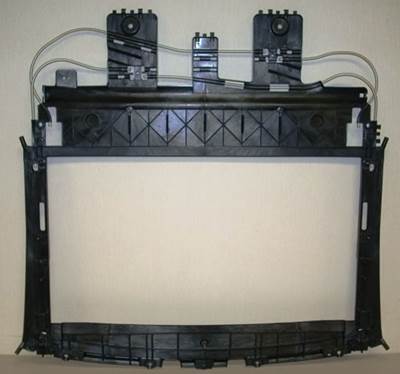

Read MoreLargest Aluminum Injection Mold Ever

Unique Tool & Gauge, Windsor, Ont. (unique-tool.com), completed a production injection mold machined from the largest block of tooling-grade aluminum ever forged.

Read MoreTips and Techniques: Mold Filling Analysis Now You Can Adapt Injection Mold Filling Simulation for MuCell

While mold-filling simulation is a very common tool for predicting the fill patterns of an injection mold, in our judgment there is not yet a commercially available, satisfactory filling simulation for microcellular foam molding.

Read More