Molds & Tooling

K 2010- Injection Molding New All-Electrics & Hybrids Balance Performance & Economy

The world’s largest plastics show, coming up next month in Dusseldorf, Germany, provides ample evidence of the growing sway of electric drive technology in injection molding.

Read MoreTooling: Setting Up a Mold Shop: Part I

I had a toolmaker once tell me he used to slam his hand in his car door before work every morning just to get him in the right frame of mind to work in his shop.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

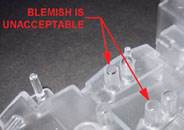

Read MoreFlow Analysis Gets It Right the First Time

This molder's trial parts showed visible flaws that made them unusable. Simple changes in tooling, processing, or materials couldn't fix it. But flow simulation provided an answer that worked right off the bat.

Read MoreUnscrewing Molds Go Electric

Hydraulics are the usual power source driving unscrewing cores to separate threaded parts from injection tools.

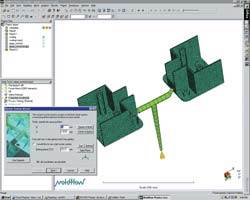

Read MoreMolding Simulation Gets Easier Than Ever

In the mid-'90s, when Peter Rucinski worked for a plastics resin supplier, he broke his company's record by performing 30 mold simulations in one year.

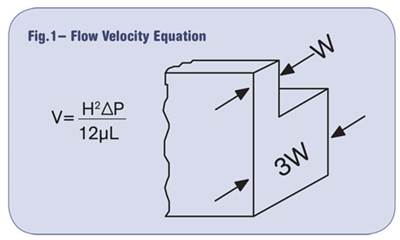

Read MoreSecrets of Successful Thin-Wall Molding

Demands to create smaller, lighter parts have made thin-wall molding one of the most sought after capabilities for an injection molder.

Read MoreDetermining Maximum Mold Cycle Counts

The first production meeting with my new employer went something like this: “We want you to establish a preventive maintenance program that is based on cycle counts for all our molds.” Before I could launch into an explanation of how best to determine maximum cycle counts, I was hit with this: “So, how many cycles do you think our molds can safely run before we need to clean them?”Leaving my crystal ball at home and unable to get my x-ray vision working, there was no way to answer that question with any accuracy.

Read MorePlastics Training Enters Virtual Reality

Plastics processors are discovering two employee training programs initiated this year that offer instruction in a “virtual” space, where the student can interact with the instructor and course materials via a satellite dish or the internet.

Read More