best practices

Benchmarking Simulation Software: How One Molder Did It

Injection mold simulation has become a standard tool for molders and mold designers.

Read MoreAdd a Layer of COC to Boost Polyolefin Film Properties

As a discrete layer in coextruded polyolefin film, cyclic olefin copolymer provides higher modulus, greater heat resistance, improved thermoformability, and increased barrier

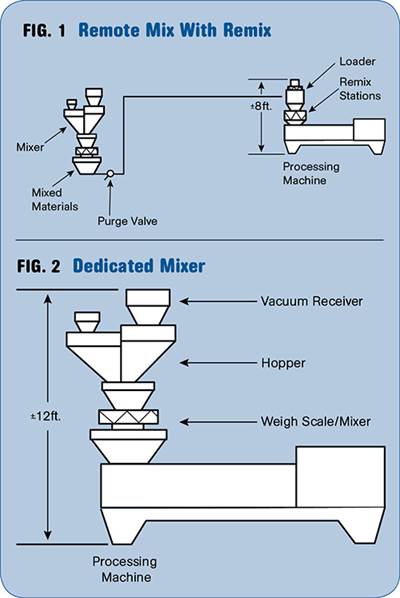

Read MoreGet to Know Your Gravimetric Blender

The introduction of gravimetric blending technology has impacted virtually every corner of plastics processing. Here's what you need to know to keep them operating at their best.

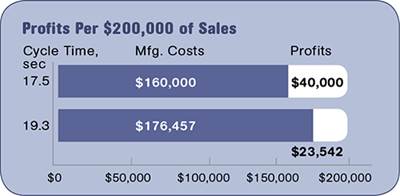

Read MorePlasticating Rates: Your Profits Are at Stake

To get the best cycle time you need the right machine, and few molders take the time to specify this critical component of the process.

Read MoreHow Fillers Impact Extrusion Processing

Their addition can significantly change the processing properties of a polymer.

Read MoreCentral or Portable? ‘Off-the-Floor’ Central Chillers Cost Less, Provide Processing Gains

In deciding whether to use portable or central chillers, there are a variety of variables to consider. Here are the key issues.

Read MoreCentral or Portable? Flexibility Favors ‘Discrete’ Chillers

Why might discrete chillers be a solution in your plant? In a word: Flexibility. Here is the lowdown.

Read MoreHow to Keep Your Conveyor Running Smoothly

Low-profile conveyors are ubiquitous in industry, typically used in 24/7 applications in packaging, assembly, labeling, inspection, and sorting. Here's how to keep them up and running.

Read MoreOn Site: Evolution of a One-Stop High-Tech Thermoformer

A company that started as a toolmaker has evolved into a thermoforming solutions provider

Read MoreCalculate Shot Size Vs. Barrel Capacity

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

Read More