best practices

A Pioneer in ‘Clean Compounding’

When Plastics Color Corp., based in Calumet City, Ill., established a new compounding plant in Southern California, the firm decided this couldn’t be an ordinary color/additive masterbatch facility.

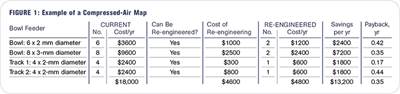

Read MoreEnergy Miser: Reducing Compressed-Air Usage

Many manufacturing sites operate on the assumption that compressed air is free. Usage is totally uncontrolled, and open air lines cost real money.

Read MoreNovel Fuel Systems Power Blow Molder’s Growth

Nano technology gives The Plastics Group a leg up on developing fuel systems for non-automotive applications

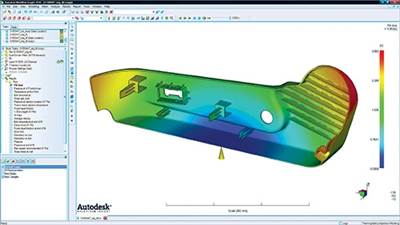

Read MoreMold Filling Simulation: What, When, Why, How

Mold-filling analysis is the right direction to go, but if you want to arrive at your destination—good parts and an efficient process—you’ll need to pay attention to all the details and select an experienced professional to do the analysis.

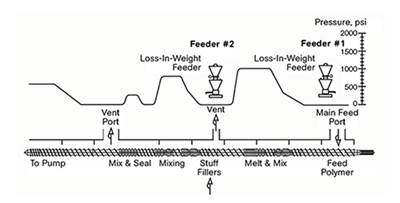

Read MoreLook Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

Read MoreEight Steps Toward a Seamless Mold Transfer

It’s big news when an OEM decides to move a substantial number of molds from one processing operation (either their own in-house/captive facility or an outsourced molder) to another.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

Read MoreOn Site: Tailoring Medical Solutions… Sometimes in 50-lb Lots

Smaller volumes teams with higher quality and value as keys to the success of this growing medical compounder.

Read MoreLook Upstream to Avoid ‘GIGO’ Pitfalls in Extrusion

You may think you have a feeding issue when in reality your problem may be upstream.

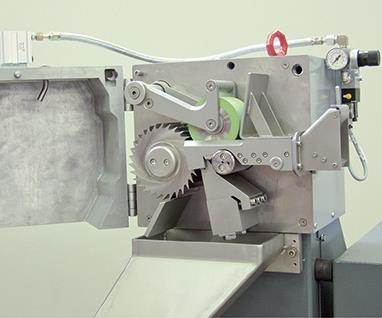

Read MoreFollow These Tips to Select the Right Pelletizer

Start by assessing the status quo, as well as defining future needs. Develop a five-year projection of materials and required capacities. Short-term solutions very often prove to be more expensive and less satisfactory after a period of time. Most of all, know your options.

Read More