best practices

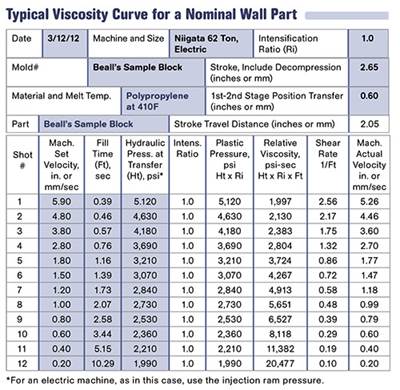

Understanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreCures for Common Hot-Runner Wiring Problems

In the challenging environment of the last several years, manufacturers are looking inward to improve their manufacturing processes, streamline their supply chains, lower maintenance costs, andimprove their bottom lines.

Read MorePowder Injection Molding Helps PTI Thrive in Specialties

“We like challenges. We like to do things that other people are scared to do.”

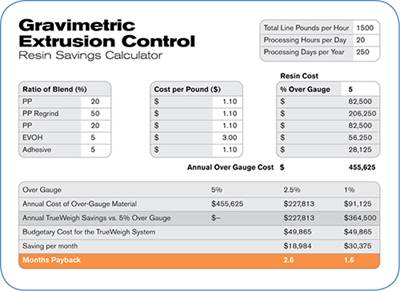

Read MoreHow Gravimetric Control Systems Pay Off in Blow Molding

Gravimetric control systems offer blow molders improvements in processing efficiencies above and beyond their ability to regulate resin usage.

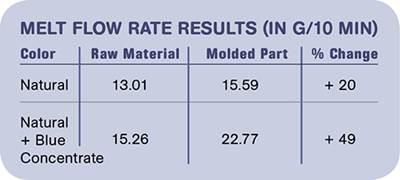

Read MoreWorking with Color Concentrates

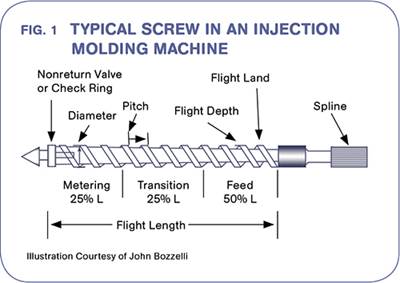

Industry needs more development of enhanced-mixing screws.

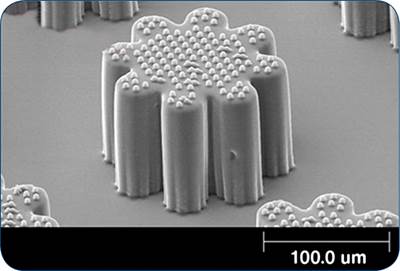

Read MoreSecrets of Success in Micro Molding

Medical-device, electronics, and biopharmaceutical manufacturers need new micro-molded products to create tinier, less invasive, and/or space-saving micro devices.

Read MoreCustom Profile House ‘Flexes’ Processing Muscle

Specialty house avoids commodity markets and has entered the proprietary processing business with new product offering.

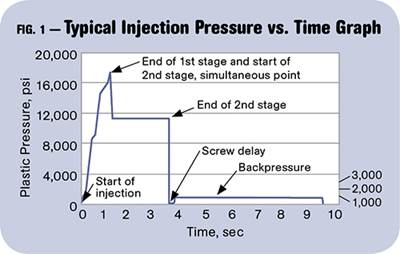

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreWorking with Color Concentrates

Perhaps the greatest difficulty involving the use of color concentrates is specifying them appropriately for the material to which they are being added.

Read MoreFive Cases Where Microcellular Foaming Paid Off

The MuCell process for producing microcellular injection molded parts is used and accepted globally as a technology option for providing a more dimensionally stable part through a reduction in residual stress, along with increased productivity versus solid injection molded parts.

Read More