best practices

Shutting Down & Starting Up An Injection Molding Machine

Whether your press is going down for repairs, a holiday, or a slow production schedule, proper shut-down and start-up procedures must be followed.

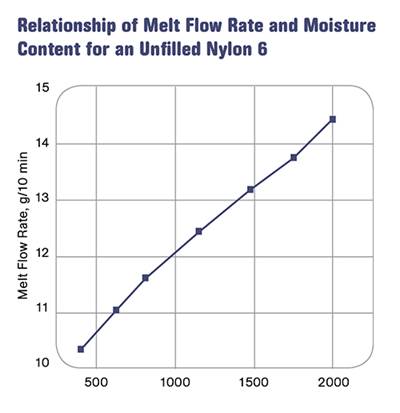

Read MoreMelt Flow Rate Testing–Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier.

Read MoreMRPC Takes ‘Holistic’ Approach To Scientific Molding

Last year this family-owned molder made a major commitment to Scientific Molding by starting a training process involving all employees.

Read MoreDon’t Overlook Gate Location

Molders take heed: Gate location is the root cause of many molding difficulties. You’ll be doing yourself a big favor by spending some time and thought in determining the best gate location. Here’s what to look for.

Read MoreFrom Printer to High-End Extruder: Colormasters Sets Sights on Collation Film

When long-established printing and converting company Colormasters was putting together a strategic plan for growth, it added blown film processing to the mix.

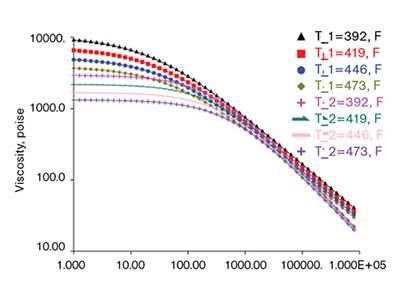

Read MoreMold Simulation: Get Best Results With Good Materials Data

Want the best results from your flow analysis software? Of course you do. But you stand a better chance for success if you pay particular attention to the material data used by the software.

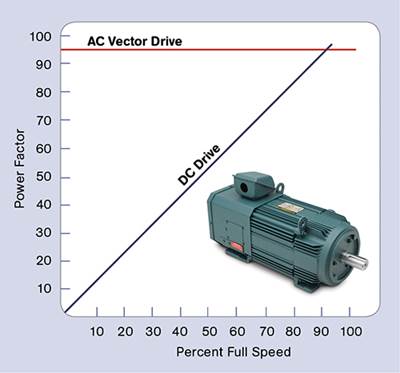

Read MoreAC Drives Take Hold

With progress in electronics and the introduction of the flux vector drive using complex control algorithms, AC drives are now equal to or better than DC drives for most applications.

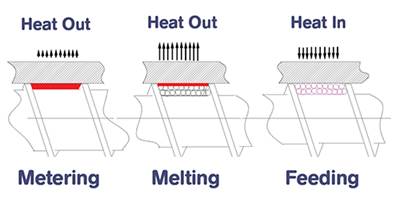

Read MoreTelltale Temperatures

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

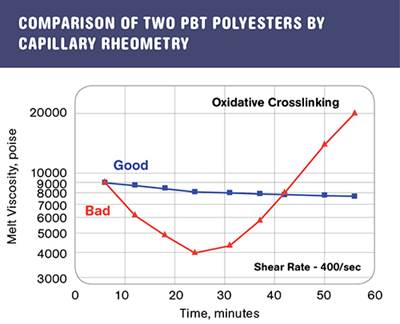

Read MoreHow to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

Read More