best practices

Melt Flow Rate Testing—Part 6

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Read MoreBusting the Conformal Cooling Myths

Conformal cooling is opening up new ways of doing things with new tools to solve problems.

Read MoreA Processor’s Advice on How to Get Moisture Testing Right

Follow these four steps to ensure your results are on target.

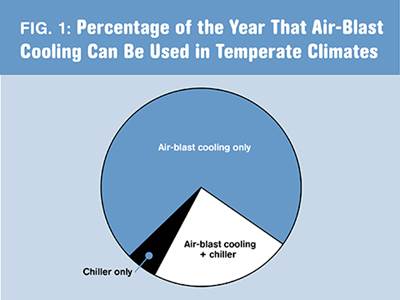

Read MoreOptimize Cooling Water Supply To Reduce Costs

In the last three articles (March, May, Sept. 2012), we introduced the problem of wasted energy in cooling-water systems and presented two types of solutions—minimizing “parasitic” heat gains and raising water temperatures to minimize demand.

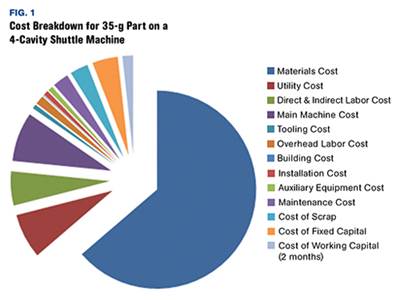

Read MoreOptimize Resin Management in Extrusion Blow Molding

In the EBM process, profits depend greatly on how judiciously you use resin.

Read MoreWhich Winder’s for You?

It's time to apply more science to the process of selecting the right kind of winder for your operation.

Read MoreMaintenance Training? Show Me the Money

Training works best if a goals are set and a plan is established to meet them.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

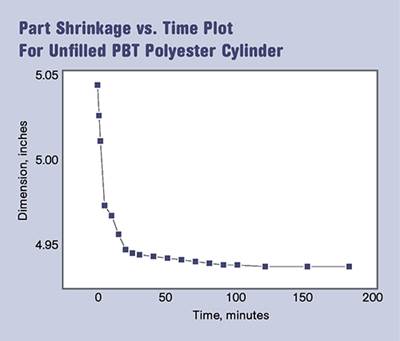

Read MoreDimensional Stability After Molding: Part 1

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

Read MoreMaking the Value Connection In Proprietary Molding

“We make components that go into other devices.

Read More