Extrusion Know How

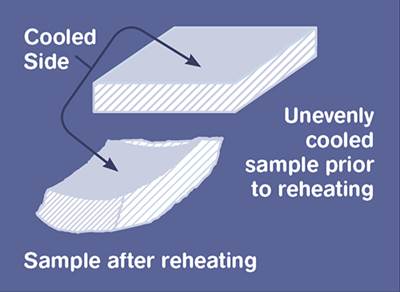

Cooling Tips for Crystalline Polymers

If a little cooling is good, is a lot of cooling better?

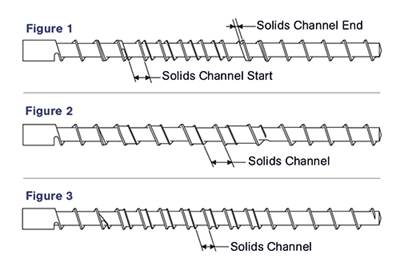

Read MoreThe Evolving Barrier Screw

There has been a gradual transition from the earlier Maillefer designs used in Europe to the Dray/Lawrence design using the parallel barrier design with an increased helix angle to accommodate wider channels.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

Read MoreScrew Design Is a Matter of Balance

In order to achieve a balance between feeding, melting, and pumping it’s necessary to use proven calculations and/or tested empirical data in the design of each section.

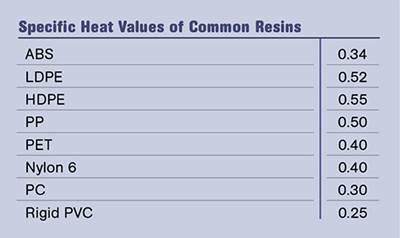

Read MoreWhat Output Should You Expect?

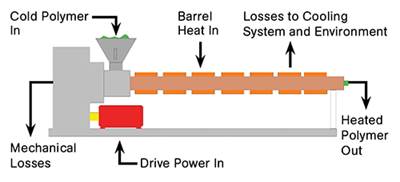

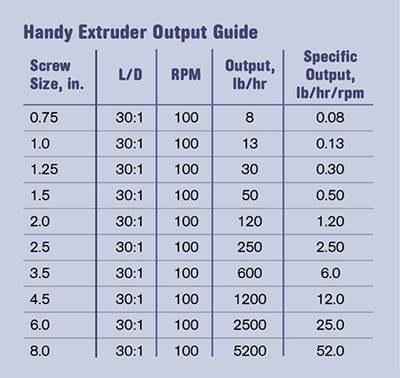

You can get a rough estimate of the potential output if you know the drive horsepower of your machine and the thermal characteristics of one of the materials you’ll be running.

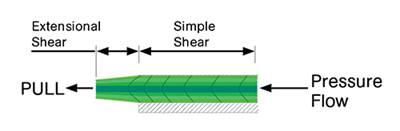

Read MoreNew Frontier for Single Screw R&D: Mixing & Melting by Extensional Shear

Extensional shear generally has been associated only with twin-screw extruders. However, I am now convinced it can be done with a single moving force (screw) by changing the geometry of the flow field perpendicular to the direction of flow.

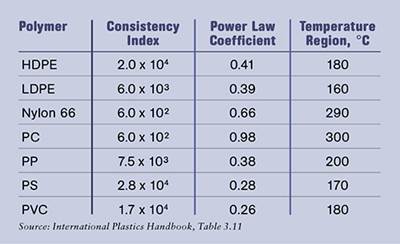

Read MoreThe Power-Law Coefficient

By referring to the power-law coefficient, the effect of barrel override in the metering section of many screws can be explained and anticipated.

Read MoreMission (Nearly) Impossible: Estimating Extrusion Melt Temperature

Extrusion processors often ask screw designers to estimate the output and melt temperature of a new design in the works. Projected output of a new screw can usually be estimated fairly accurately. Melt-temperature estimate, however, is another story

Read MoreGet Smarter on Extruder Sizes

Processors tend to recommend a much larger extruder than what’s really necessary for the job and the capabilities of the downstream equipment.

Read MoreWhat’s the Deal With High-Speed Extruders?

If we are talking about extruder screw speed, how about 1800 rpm? That’s how fast some extruders are running today.

Read More