Extrusion Know How

Screw Surging, Part III: Unfilled Discharge Section

This type of surge happens most frequently with two-stage screws when the second stage has far more capacity than the first stage. It can also happen when a screw is limited in feeding or melting, causing a partially filled metering section.

Read MoreOverfeeding Can Cause Surges, Too

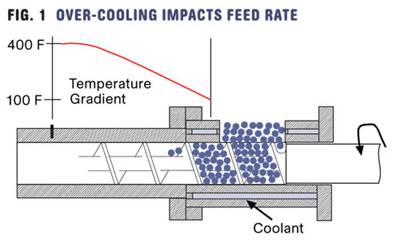

Surging can be caused by feed restrictions, as covered in another column, and also by over-feeding or under-melting, discussed here.

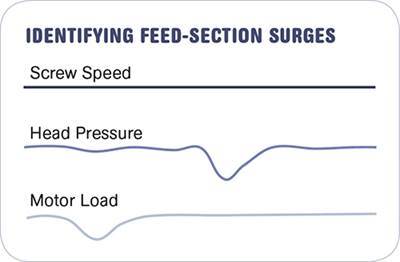

Read MoreSolving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

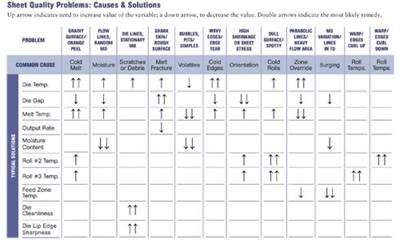

Read MoreExtrusion: A Roll Is a Roll Is a Roll?

Chill rolls may looks simple and shiny, but they play a critical part in cooling and polishing film and sheet and are not all the same.

Read MoreFollow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

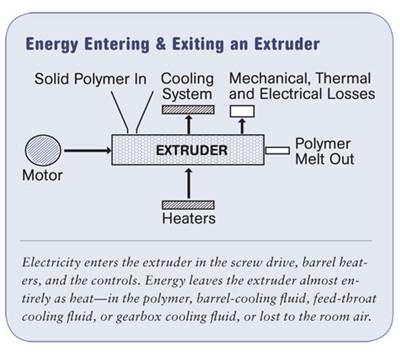

Read MoreExtrusion: Reducing Energy, Part II: ‘Adiabatic’ Extrusion

The term adiabatic extrusion was very popular in the ’60s and ’70s, but has seemingly disappeared from the processing terminology of today.

Read MoreExtrusion: Run Your Chevy Volt with Extruder Energy Savings—Part I

The electricity saved on a large extrusion line could power a number of Chevrolet Volts.

Read MoreExtrusion: Start Up and Shut Down Properly

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read More