Extrusion Know How

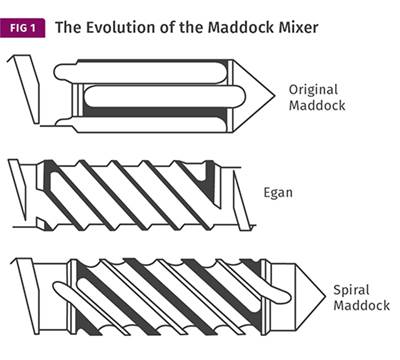

EXTRUSION: Barrier Screws and Mixers

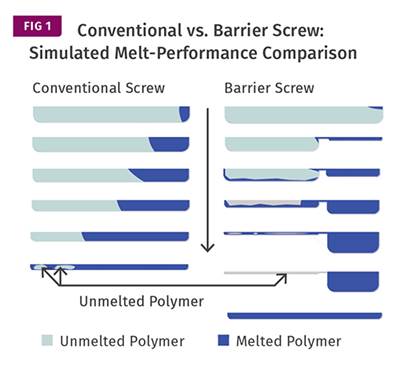

For some reason, there are a lot of barrier screws in operation with high-shear mixers, when a distributive mixer is usually a better choice.

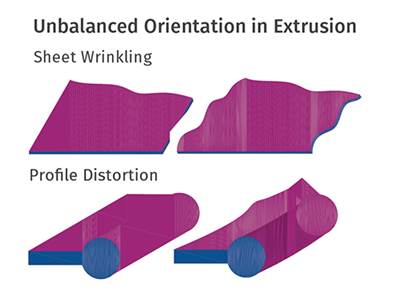

Read MoreExtrusion: How to Adjust for Polymer Shrinkage and Orientation

Polymers shrink and orient. Sometimes orientation is unbalanced, resulting in misshaped parts. But there are steps beyond tweaking the die that can mitigate these effects.

Read MoreEXTRUSION: Another Technique for Controlling Melt Temperature

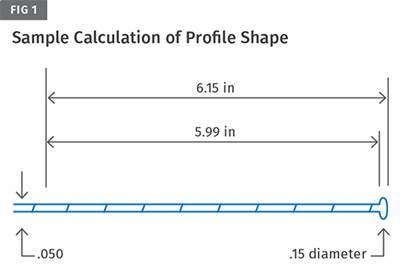

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

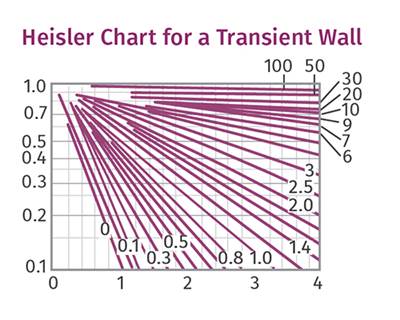

Read MoreEXTRUSION: Cooling: The Critical Function in Extrusion

Figuring out how much cooling your process needs is complicated. But there are ways to approximate.

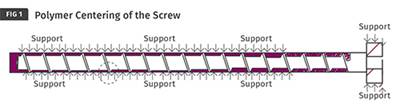

Read MoreEXTRUSION: Here’s Why You Shouldn’t Run Your Extruders Dry

At least not for longer than a few minutes. The thin film that’s captured between the screw flights and barrel wall supports the screw and acts as a lubricant. Without it, galling can occur.

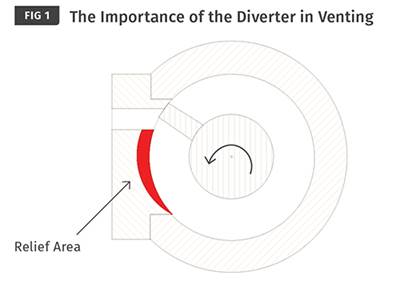

Read MoreExtrusion: What’s the Best Way to Vent?

There are advantages and disadvantages to each, and they must be evaluated before making a decision.

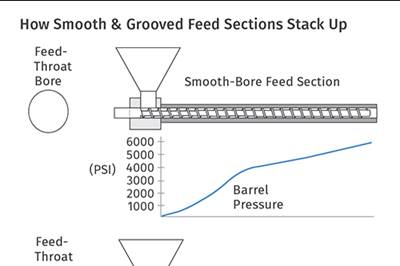

Read MoreEXTRUSION: Are Grooved-Feed Extruders Right for You?

In specific circumstances, this design can increase output and reduce melt temperature. But grooved feed throats are not for every application.

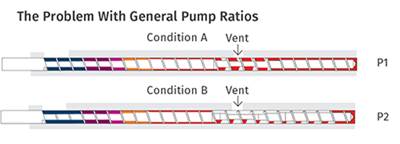

Read MoreEXTRUSION: Avoid General ‘Pump Ratios’ On Two-Stage Screws

Instead, rely on basic data and calculations to determine the proper depth of the first and second metering sections

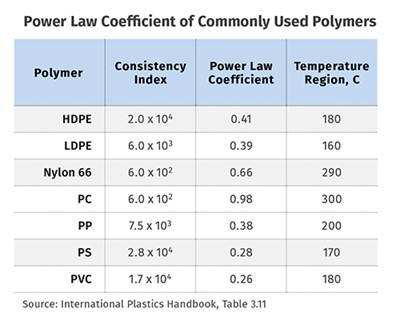

Read MoreEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

Read MoreUnderstanding Solids-Bed Breakup in Barrier Screws

Barrier screws all but eliminate problems associated with solids-bed breakup. But if they do occur, tremendous pressures can develop, causing screw wear.

Read More