Extrusion Know How

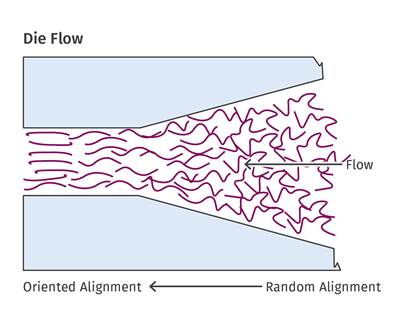

EXTRUSION: Orientation: The Good and the Bad

Depending on what you are trying to accomplish, molecular orientation can have a positive or negative impact on your part. Here’s how to control it.

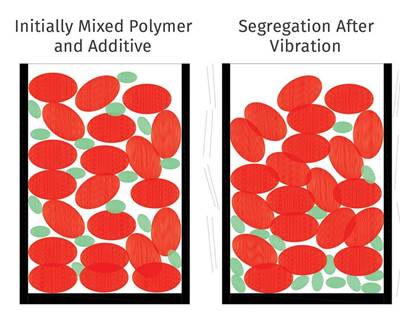

Read MoreEXTRUSION: Better Mix In Means Better Mix Out

Segregation or de-mixing of polymers and additives can be a big problem in single-screw extrusion. Here’s why it happens, and how to fix it.

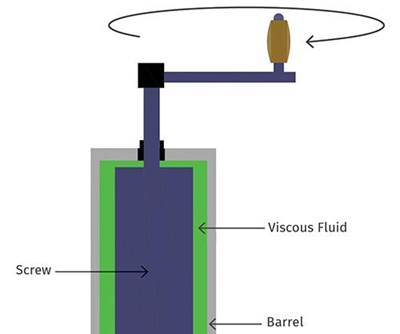

Read MoreEXTRUSION: How Slow Can You Go?

Larger screws designed for high outputs will generate a variety of problems if run too slowly. Here’s why.

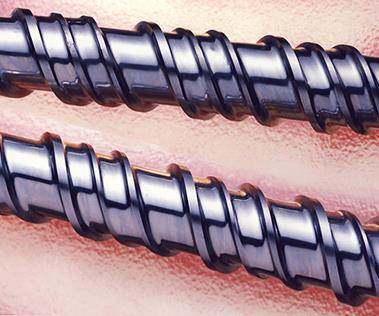

Read MoreEXTRUSION: Finding the Sweet Spot in Screw Design

The compression ratio of a screw does not provide enough detail on how it will perform. Screw design is a balancing act that takes many variables into account.

Read MoreEXTRUSION: Understanding The Barrier Gap

All barrier screws are not created equal, and the barrier length and gap can be one of the reasons.

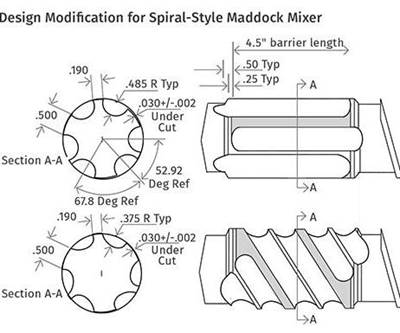

Read MoreEXTRUSION: Venerable Maddock Mixer Still an Extrusion Workhorse

Variations to this decades-old mixing section are widely used, but processors should carefully analyze these designs and not assume they will perform better.

Read MoreEXTRUSION: Managing Regrind

Reusing scrap is a necessary evil. But be aware of the negative impact scrap has on properties and extrusion efficiencies. Start by developing a regrind-usage program.

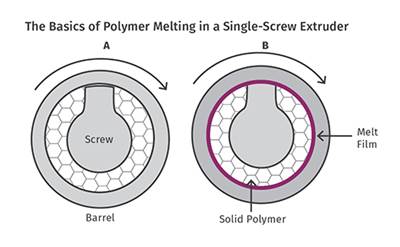

Read MoreEXTRUSION: Melting 101

Learn the basics on how polymer melts in a single screw. Barrel temperature plays less of a role than you might think.

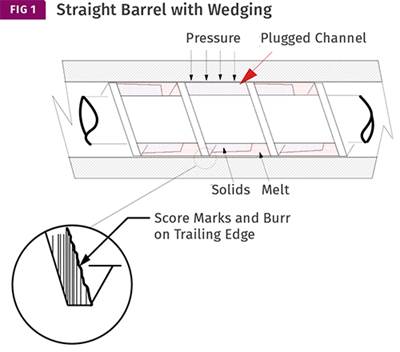

Read MoreEXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

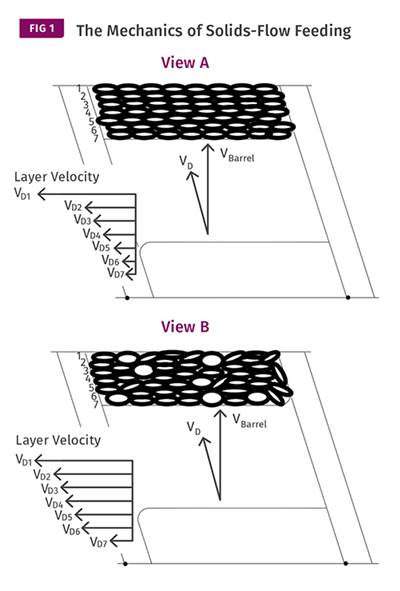

Read MoreEXTRUSION: Pellet Geometry Can Impact Output

A simple angle-of-repose experiment can help you determine how your pellets will feed.

Read More