Extrusion Know How

Extrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreTry This Lower-Cost Purging Method

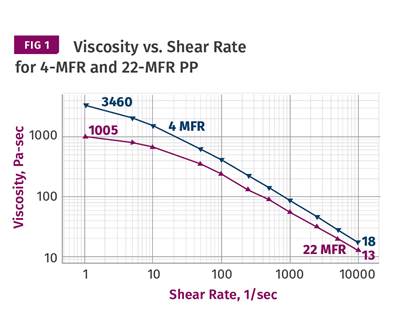

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read MoreHow to Optimize Usage of Recycled Material

Processors need to “engineer” feeding properties similar to virgin pellets into their regrind to efficiently and economically utilize more of their scrap.

Read MoreWhat You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

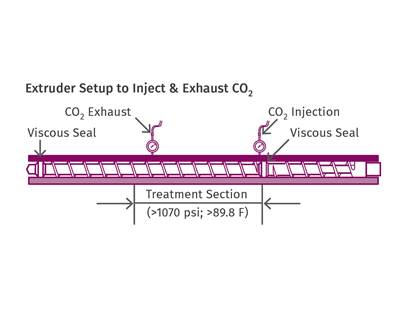

Read MoreTry This Approach to Clean Up Your Recycled Material

CO2 can be used as a totally “green” solvent to remove many kinds of contamination in recycled plastics without the need for toxic solvents.

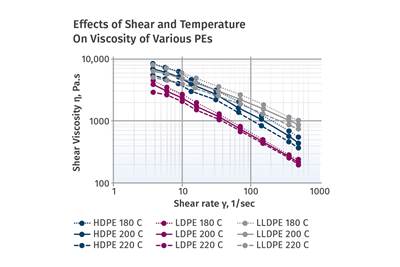

Read MoreUnderstanding Viscosity in Extrusion

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

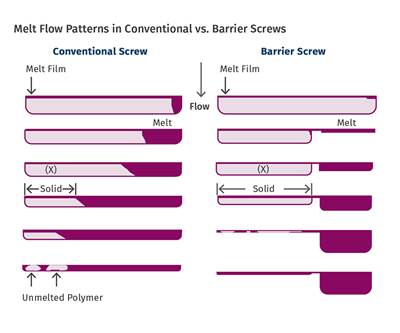

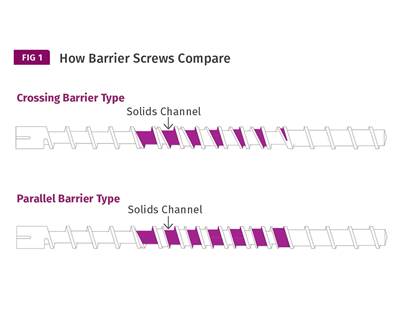

Read MoreBarrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

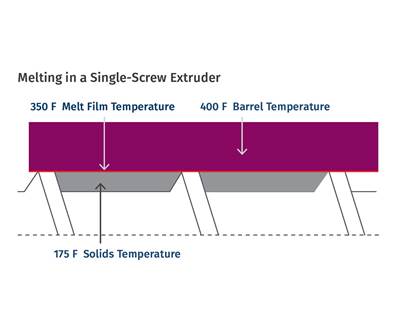

Read MoreWhy Barrel Temperatures Have a Small Effect on Melt Temperature

Extruders are not like ovens. Tweaking barrel-temperature profiles will not influence melt temperature all that much. Here’s why.

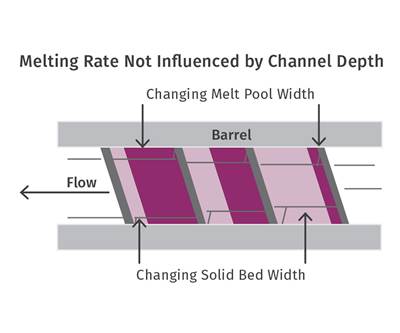

Read MoreSimple Scale-Up Calculations for Melting

You can avoid complicated melting equations when designing or evaluating a screw by using simpler methods that can save time and provide good results.

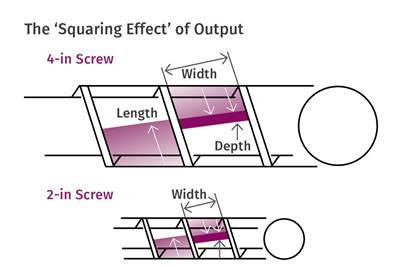

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read More