Extrusion Know How

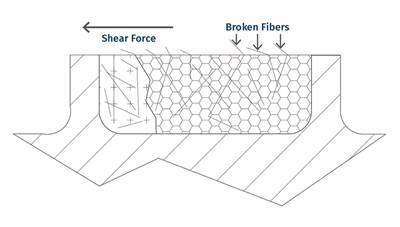

Put Science into Glass-Fiber Compounding on Single Screws

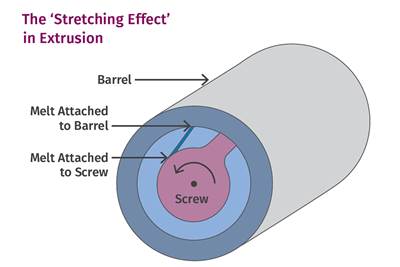

There are still companies that compound glass fibers on single screws. The process is considered an “art,” but can be made more predictable with attention to screw design, speed and length, as well the choice of mixer.

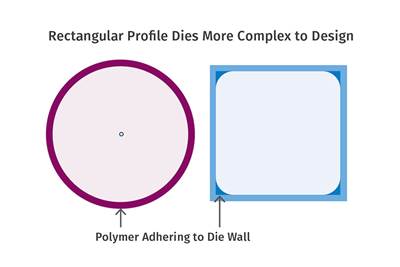

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreGeneral-Purpose Screws on the Comeback?

They are being specified more often for recycling applications to increase flexibility. But there is still no such thing as a GP screw and recyclers need to consider other processing approaches.

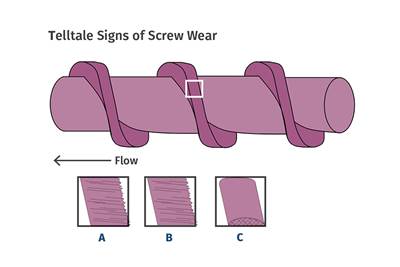

Read MoreThe Three Causes of Screw Wear

You run the risk of wasting time and money by not understanding what’s causing your screws to wear.

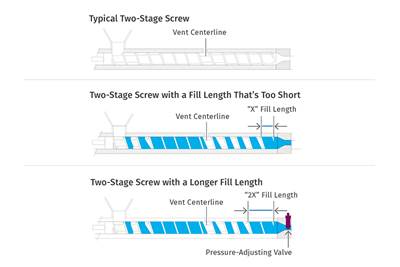

Read MoreExtrusion: Solving Surging in Two-Stage Screws

This usually crops up when the two stages are not matched in output. The best solution is to install a pressure-adjusting valve at the discharge end of the extruder.

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

Read MoreExtrusion: Evaluating Screw Design for Multi-Material Recycling

Since many plastic products are made of a combination of materials with very different melting points, careful consideration must be given to designing screws when it comes time to recycle these products.

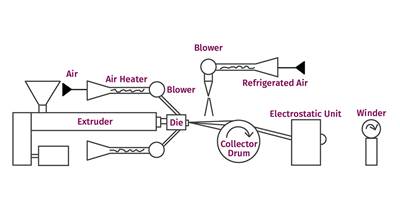

Read MoreExtrusion: 'Melt-Blown' Fiber: What You Need to Know to Enter the Face Mask Market

Coronavirus pandemic has made extrusion processors curious about entering the face-mask market. But melt-blown fiber is very different from most other extrusion processes and requires specialized equipment.

Read MoreExtrusion: The Importance of Zone 1 Barrel Temperature

Tweaking the temperature settings of the first barrel zones may not yield the desired result. In fact, they may yield the opposite. Here’s why.

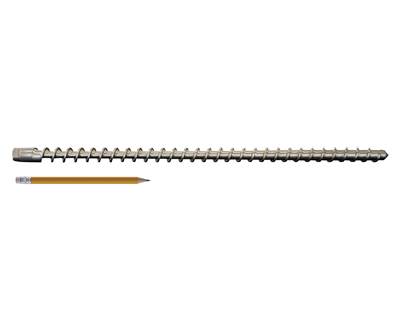

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

Read More