Extrusion Know How

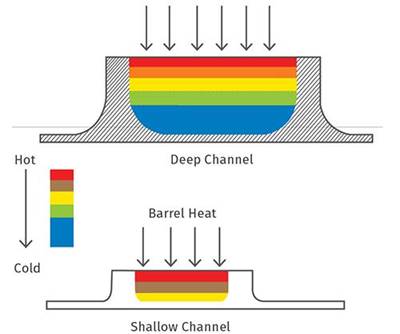

The Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreScrew Design Tips to Boost Productivity

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankland and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

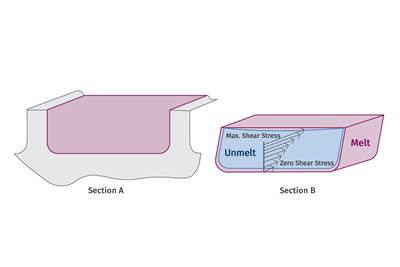

Read MoreWhat You Need to Know About the Design and Operation of Maddock Mixers

Designed properly, all entering solid polymer fragments and certain types of PE gels entering the Maddock mixer can be trapped and dispersed into the matrix resin. But many are not properly designed. Here’s what to look out for.

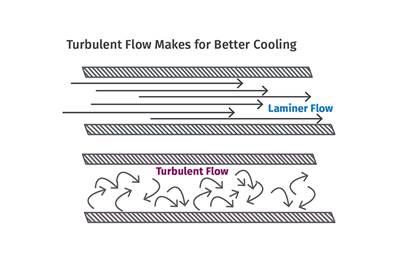

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

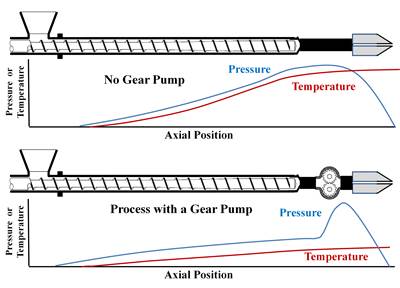

Read MoreIs a Gear Pump Right for Your Single-Screw Operation

As with everything else, there are pros and cons, but more of the former. They provide processors higher rates while decreasing the temperature of the extrudate while enabling downgauging.

Read MoreStop Shopping for a 'Jack of All Trades' Extruder

Some processors try to find “fits all” extruders to cover all processing possibilities. But you’d have to grossly overpower it to achieve this, and that’s expensive up front and will result in inefficiencies over time.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

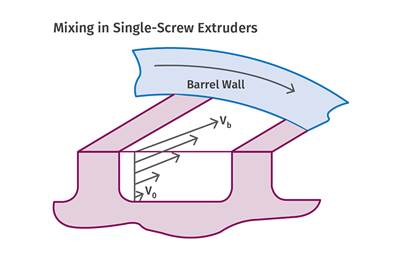

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read More