Extrusion Know How

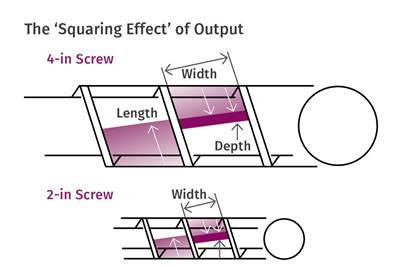

Unraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

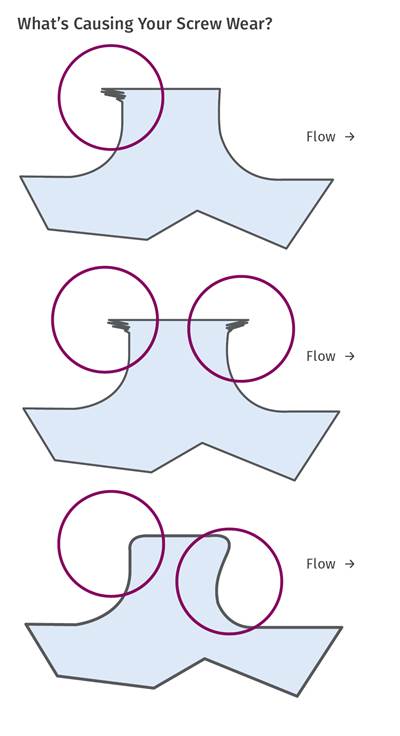

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

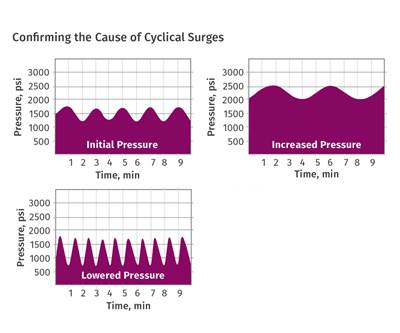

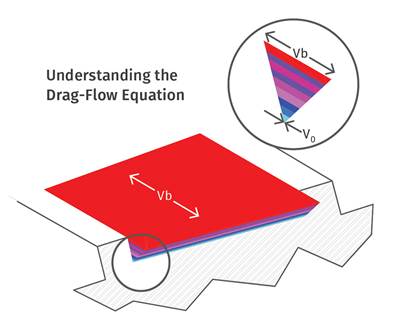

Read MoreExtrusion: Head Pressure and Output Stability

Use drag- and pressure-flow equations to analyze fluctuating output.

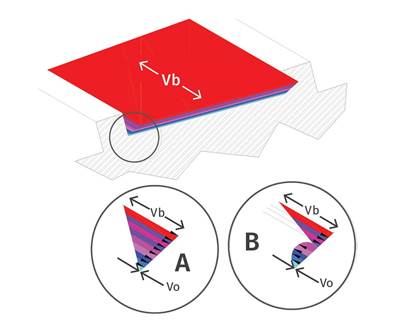

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read MoreExtrusion: A Simple Way to Evaluate Extruder Screws

While there’s lots of data that influences screw design, processors usually don’t have access to it. So instead, try calculating drag flow to see if your screw is working properly.

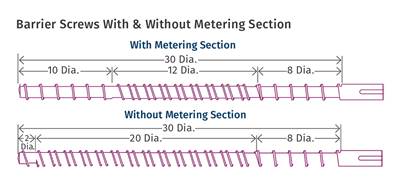

Read MoreExtrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

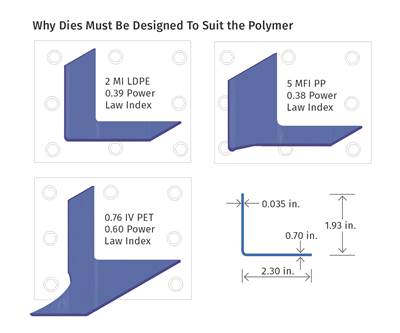

Read MoreExtrusion: Why There Are No Truly Universal Dies

Flow characteristics of different polymers vary considerably. So while adjustment features are available, for the most part dies must be designed for an individual polymer.

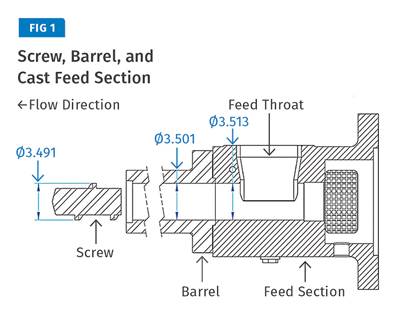

Read MoreCast vs. Integral: Which Feed Section Is Best for You?

Here are seven factors extrusion processors should weigh to help them decide between cast feed section versus an integral extrusion feed section.

Read MoreExtrusion: Understanding Weld Failures

Hard-surfacing failures without evidence of burrs indicate possible weld bond issues.

Read MoreExtrusion: How Hopper Crammers Can Help Feeding

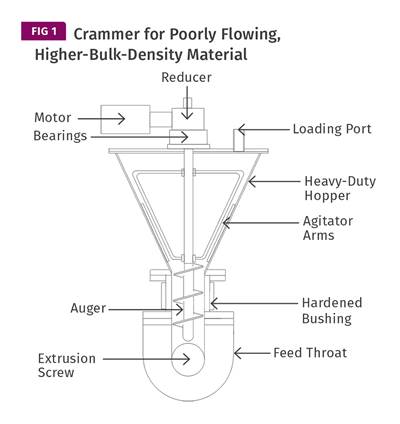

A crammer can assist the flow of certain polymers into the extruder. But the design is not universal and very material dependent. Here’s what you need to know.

Read More