Extrusion Know How

New Extrusion Equipment Combines U.S. Management with Chinese Production

Starting up in 2011, Uway Extrusion has begun its commercial push this year, with plans to exhibit at NPE2015 next March.

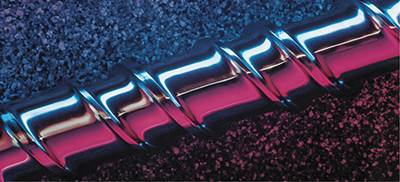

Read MoreEXTRUSION: Why Bother to Chrome Plate Your Screws?

It doesn’t add that much to the overall cost and can improve performance and facilitate maintenance. So the better question is: Why not?

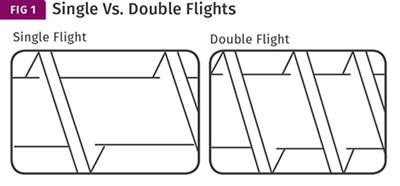

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

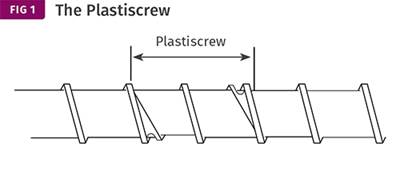

Read MoreEXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

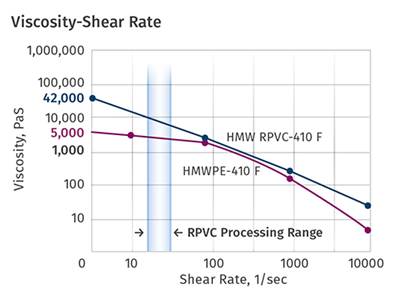

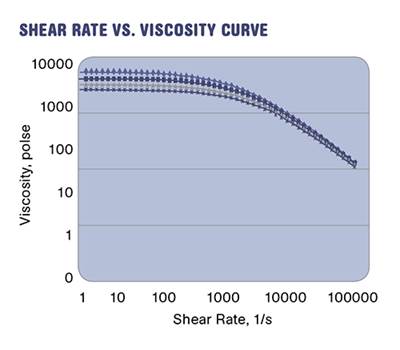

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

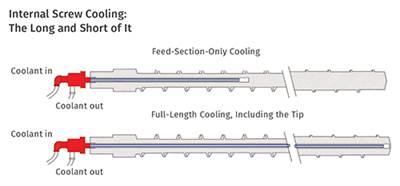

Read MoreEXTRUSION: When Internal Screw Cooling Makes Sense

Internal screw cooling could help you solve solids-feeding and burning problems.

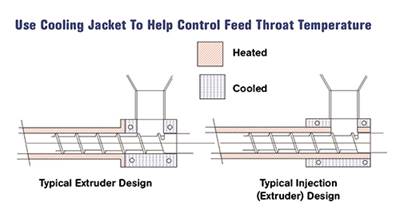

Read MoreEXTRUSION: What’s the Right Feed Throat Temperature?

Selecting the proper one is critical to the process.

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

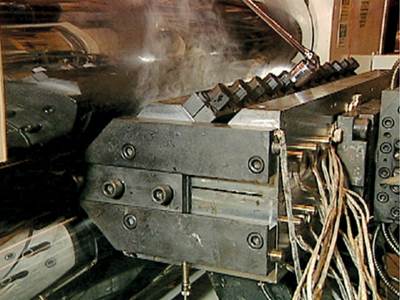

Read MoreExtruding High-Temperature Resins

Older extrusion lines might not be suitable for processing materials up to 750 F. Here's what you need to know to get started.

Read More